Translate this page into:

Production acceptance trial of indigenous manufactured helmet: Field experience and lessons drawn

*Corresponding author:Murtaza,Station Medicare Centre, Air Force Station, Bidar, Karnataka, India.docmurtu@rediffmail.com

-

Received: ,

Accepted: ,

How to cite this article: Murtaza. Production acceptance trial of indigenous manufactured helmet: Field experience and lessons drawn. Indian J Aerosp Med 2022;66:90-3.

Abstract

Effective trial of indigenously developed flying clothing like a helmet on aircrew is important before final acceptance. The prototype indigenously designed helmet by an Indian manufacturer was subjected to a final Production Acceptance Trial (PAT) at a flying base for operational capability. Ground and in-flight evaluation of helmet was conducted involving aircrew. Most of the parameters for trials were satisfactory. Certain observations were brought out by the aircrew and trial team, which were later rectified by the manufacturer. The rectified helmet was subjected to repeat PAT and finally accepted for bulk production. This paper highlights the importance of such trials, lessons drawn, and recommendations for future trials.

Keywords

Prototype

Production acceptance trial

Aircrew helmet

INTRODUCTION

Flying clothing like an aircrew helmet is an important aspect of aircrew support equipment inside an aircraft cockpit.[1] Various parameters of helmet such as sizing, fitment, noise attenuation, visor quality, the Field Of Vision (FOV), and integration with a mask are critical to assist aircrew in flying duties and provide protection.[2,3] Laboratory testing and trial of flying clothing like a helmet on aircrew are critical before final acceptance.[4] The development and acceptance of aircrew helmet is achieved in stages such as defining requirements, laboratory tests, and determination of operational acceptability by conducting appropriate ground and flight trials involving the user aircrew population.[5-8] The Production Acceptance Trial (PAT) for an indigenously developed helmet was conducted at a flying base to assess the integration of the indigenous helmet with the mask and other components of the aircraft. The objective was to obtain feedback from the pilot population and identify issues regarding various aspects of the suitability of helmet from the user’s point of view. PAT is a critical step to identify shortcomings and make rectifications before indigenously developed flying clothing like helmet is finally accepted for use in services. This paper brings out various aspects of PAT for indigenously developed helmet, lessons drawn, and recommendations for future trials.

THE APPROACH

The composition of the trial team included – DRDO scientists, air HQ flying clothing cell representatives, aerospace medicine specialists (The author), and the vendor representative. Indigenously designed helmets Figure 1, Original Equipment Manufacturer (OEM) helmets, indigenously designed masks, helmet assessment questionnaire, and Vernier caliper Figure 2 were used for the PAT. A total of eight male aircrews of varied seniority and experience and current on aircraft type participated in the trial. The age range was between 23 and 40 with a mean ± SD of 30.25 ± 5.23 years. The weight range was between 62 and 75 with a mean ± SD of 68.07 ± 4.16 kg. The flying experience of the subjects in the form of flying hours was 881.25 ± 636.85 as mean ± SD. Size correlation between Indian and OEM (ALPHA) helmet with corresponding head dimensions was done to select the appropriate subject for the correct helmet size.

- Helmet with padding and edge rolls.

- Measurement of gap between visor and mask with vernier caliper

The trial was conducted in two phases, that is, the first phase of ground trial and second phase of flight trial. In the first phase of ground trial, various parameters such as overhead clearance, strength of RT/Intercom, adequacy of helmet chord length with full head movement, FOV inside, and outside of the cockpit were evaluated [Figure 3]. Overall integration of helmet with mask, operational maneuverability, comfort, and neck movement was assessed. In the second phase of flight trial, day and night sorties were planned with various exercises such as composite, low level tactical, and NF to check the overall operational acceptance of helmet. At the end of both phases of trials, helmet assessment sheet (Debrief form) was filled up by aircrew to obtain feedback [Table 1].

- Cockpit trial depicting visor mask gap.

| S. No. | Parameter | Tick appropriate option | Responses in % |

|---|---|---|---|

| 1. | Donning and doffing | Very cumbersome difficult easy very easy | Easy-87.5 |

| 2. | Fitment and padding | Uncomfortable average fit snug fit | Snug fit-87.5 |

| 3. | Does head movement cause helmet to loosen | Yes No |

No-100 |

| 4. | Retention under “G” | Yes No |

Yes-100 |

| 5. | Visor transparency | Clear acceptable not clear | Clear-75 Acceptable-25 |

| 6. | Visor refractive index/power | Nil slight unacceptable | Nil-87.5 |

| 7. | Visor distortion | Nil slight unacceptable | Nil-87.5 |

| 8. | Visor retention in flying maneuvers | Good acceptable unacceptable | Good-100 |

| 9. | Visor cut | Less adequate more | Less-87.5 |

| 10. | Gap b/w visor and mask | Nil acceptable unacceptable | Unacceptable-87.5 |

| 11. | RT strength on ground | 1,2,3,4,5 | Strength 5-100 |

| 12. | RT strength in air during maneuvers | 1,2,3,4,5 | Strength 5-100 |

| 13. | Any break in continuity in RT | Yes No |

No-100 |

| 14. | Which mask was used ex-import Indian | Ex-Import-25 Indian-75 |

|

| 15. | User satisfaction level | Rate from 1-5 | Rating 2-12.5 Rating 3-37.5 Rating 4-50 |

| 16. | Suggestions for improvement | Visor Mask gap needs reduction. | |

| 17. | Comparison with original equipment manufacturer helmet | More comfortable comparable less comfortable | More comfortable-25 Comparable-62.5 Less comfortable-12.5 |

DISCUSSION

PAT is one of the steps of the multistage development protocol of indigenous flying clothing. It is done as a final step to obtain user population comments on sample manufactured by the vendor before prototype flying clothing goes into bulk production and induction into services. Before PAT, flying clothing is tested mainly in laboratory settings and only on a few aircrews. A few issues may still be missed in early steps of the developmental protocol. PAT is finally aimed to address any such issue. PAT was conducted at a flying base involving an aircrew for accepting an indigenously developed helmet for use in services. Most of the aspects of trial were satisfactory except for a few observations brought out in the trial. Helmet parameters such as donning and doffing, fitment and padding, comfort under high G, RT strength, visor transparency, refractive index, and distortion were found satisfactory. Although most of the helmet sizes matched the corresponding sizing schedule, a couple of aircrews had to change the size of forehead roll to achieve better fitment. Extra forehead rolls with extra width amounting to 5% of each bulk production were recommended to be supplied by the vendor to cater to uncommon sizes. A couple of subjects reported higher magnification of the Main Instrument Panel (MIP), which indicated visor may be defective in terms of refractive index. The Qualification Test Procedure (QTP) includes all tests for testing visor parameters but QTP is not done on the entire bulk production of visors by the vendor, creating a possibility of defective visors being fitted in the helmet. The Certificate Of Conformance (COC) which confirms that QTP has been performed on sample visors from the vendor was also not mentioned as a prerequisite before being accepted for trials. It was recommended that sample visors to be tested for an optical property by the manufacturer and that COC be obtained before being subjected to user trials. Military specification document MIL-DTL-43511D for visors, specify random testing of visors to ensure Quality Assurance (QA).[9] The trial team deliberated on this issue and with inputs from the DGQA agency, a/m Mil standard document and past experience of trial team, it was decided that 3% testing for each production lot will be adequate to monitor QA. UV transmittance test is to be conducted on at least one visor from the lot as it is a destructive test.[9] The majority of aircrew reported that the entire MIP was not falling within FOV through the visors. This can cause distraction in flight. When compared, the dimensions of the present polycarbonate visors were found shorter as compared to original acrylic visors. Deliberations revealed that originally two visor sizes were approved to cater to five sizes of helmets, but during trials, vendor provided two sets of visors with same sizes. From further deliberations, it emerged that there is a requirement to increase the visor dimensions to ensure that entire MIP falls within the visor FOV. It was recommended that visor dimensions be increased to match the original design of prototype. The majority of pilots reported a gap between lower edge of the visor and mask. This can be reduced if the visor is adjusted in the lowermost setting. In addition, it was deliberated that gap can be reduced by increasing the visor margin dimensions to match the original design of prototype. Poking of Scopex Mic connector under high “G” was found uncomfortable in large size helmet. It was found that connector wire loop and metal plate anchor of Scopex Mic were largely responsible for this issue. Deliberations revealed that extra wire loop could be removed along with increasing the nape pad length and reducing the forehead edge roll width to rectify the problem. Subsequently, repeat PAT was undertaken following rectifications by the manufacturer. Finally, bulk production of indigenously designed helmet was cleared and accepted.

LESSONS DRAWN

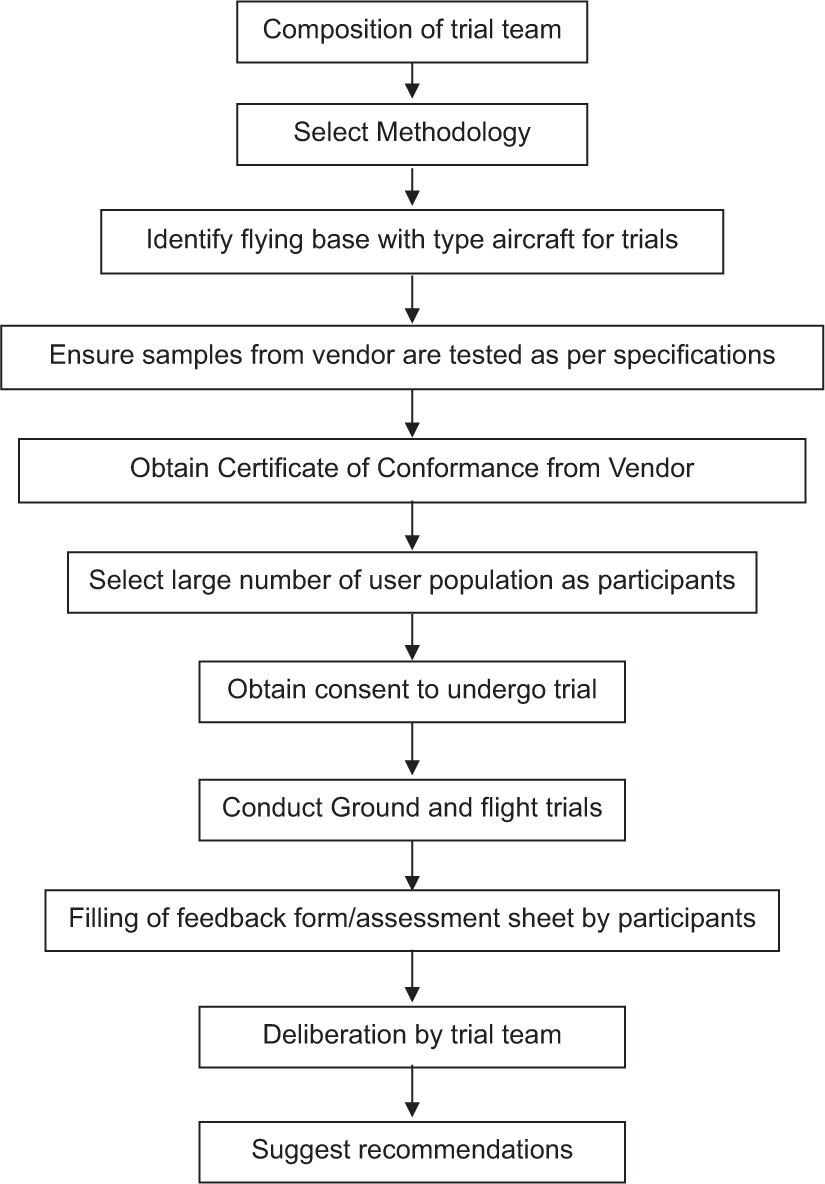

Lessons drawn are brought out in the form of a proposed protocol to conduct future such trials where the evaluation of indigenous flying clothing is under consideration. Meticulous planning, correct methodology, and importance of views of user population are the key to success of these trials. Correct composition of the team is the key to critical evaluation of flying clothing. It is valuable to include members from different streams such as scientists from manufacturer, aviation medical specialists, flying clothing cell representatives, and vendor representatives. Testing of critical parameters of flying clothing sample manufactured by vendor is important before subjecting to PAT.

PROPOSED PROTOCOL FOR PAT

CONCLUSION

The indigenously manufactured helmet prototype was subjected to PAT for final acceptance before bulk production. Involvement of aircrew, proper composition of trial team, and appropriate methodology were critical in identifying teething issues before helmet is accepted for use in services. PAT revealed certain shortcomings, which were rectified subsequently by the manufacturer. The helmet and its integration with the mask were found satisfactory for use by the end user. Rectified helmet was subjected to repeat PAT and finally accepted for bulk production. PAT is a critical step to ensure that high quality flying clothing is accepted in services for use by aircrew. Certain lessons were drawn and recommendations are made in this paper which will go long way in ensuring that these kinds of trials are conducted appropriately for maintaining flight safety and gaining long term benefits.

Acknowledgment

The author would like to thank

• Dr. T. M. Kotresh, Sc “H”

• Dr. R Ramjee, Sc “F”

• Mr. M. Revanna, Sc “E”

• Mr. Vikash Kumar, Sc “E”

Declaration of patient consent

Patient’s consent not required as patients identity is not disclosed or compromised.

Conflicts of interest

The author has none to declare.

Financial support and sponsorship

Nil

References

- Flight helmets: How they work and why you should wear one. J Air Med Transp. 1992;11:19-23.

- [CrossRef] [PubMed] [Google Scholar]

- Optimizing sizing schedules of aircrew helmets using machine learning techniques. Indian J Aerosp Med. 2020;64:18-22.

- [CrossRef] [Google Scholar]

- Sizing trials of a prototype aircrew helmet: Lessons re-learnt. Indian J Aerosp Med. 2009;53:44-52.

- [Google Scholar]

- Evaluation of indigenous flying clothing-ASTE's experience. Indian J Aerosp Med. 1997;41:27-9.

- [Google Scholar]

- Development and Certification of Flying Clothing (1st ed). India: Technical Mini Series in Aerospace Medicine; 2005.

- [Google Scholar]

- Evaluation of High Performance Helmet and Oxygen Mask. Defence and Civil Institute of Environmental Medicine Report No 82-R-54.

- [Google Scholar]

- Optical and Biodynamic Evaluation of the Helmet. US Army Aeromedical Research Laboratory Report No. 98-22.

- [Google Scholar]

- Qualitative Evaluation of Aircrew Helmet Passive Noise Reduction and the Communications Earplug for Tactical Aviation. In: Proceedings of the Human Factors and Ergonomics Society 45th Annual Meeting. United States: SAGE; 2001.

- [CrossRef] [Google Scholar]

- MIL-DTL-43511D, Detail Specification: Visors, Flyer's Helmet, Polycarbonate [superseding MIL-V-43511C] 1990. EverySpec. Available from: http://everyspec.com/MIL-SPECS/MILSPECS-MIL-DTL/MIL-DTL-43511D_15101/

- [Google Scholar]