Translate this page into:

Windblast testing of an aircrew helmet: An approach to neck load analysis

*Corresponding author: Dr. NK Tripathy, MBBS, MD, Senior Advisor (Aerospace Medicine) and Chief Research Officer, Institute of Aerospace Medicine IAF, HAL Old Airport Road, Vimanapura, Bengaluru - 560 017, Karnataka, India. nktdoc@yahoo.com

-

Received: ,

Accepted: ,

How to cite this article: Tripathy NK, Divya N, Raghunandan V. Windblast testing of an aircrew helmet: An approach to neck load analysis. Indian J Aerosp Med 2019;63(2):77-82.

Abstract

Introduction:

Modern generation fighter aircraft has expanded the escape envelope for a fighter aircrew. With the ejection occurring at very high airspeeds, windblast is a cause of major injuries and fatalities. Flying helmet, before its induction into operational usage, must be tested in simulated windblast conditions to ensure that they provide adequate safety.

Material and Methods:

Windblast tests were conducted on a newly designed/procured helmet in a standard windblast test facility as per Mil Std MIL-V-29591/1. A large instrumented Hybrid III male dummy was used for the tests. The test conditions were: Wind speed 600 ± 60 KEAS, rise time of 125 ± 20 ms, time at peak wind velocity of 300 ± 50 ms, and total exposure time of ≥3 s. Structural integrity, retention with the headform, and recorded neck loads were assessed for interpretation of test results.

Results:

Helmets could withstand the windblast conditions without any significant structural failures and were retained with the headform during the entire duration of test conditions. However, analysis of the neck loads resulted in a significant dilemma in aeromedical decision-making, there being no laid down criteria in the Mil Specification. The neck tension forces were more than the acceptable limits and found to have the potential for significant neck injuries as per the Injury Assessment Reference Values specified in AGARD-AR-330 specifically in the tests where blast was head on and outer visor in up configuration; however, these values were within the acceptable limits as per the other proposed criteria. Similarly, analysis of the neck tension extension combined effects revealed conflicting outcomes for Nij performance limits specified in various standards. This paper discusses the critical analysis of neck loads vis-à-vis the neck injury criteria to understand the neck loads generated during windblast conditions and its implication on aircrew safety.

Conclusion:

Neck loads assessment is critical in predicting aircrew safety during windblast testing. In the absence of a clearly defined criteria in the Mil Specification, critical ananlysis of neck loads vis-à-vis recommended standards in scientific literature be done to make meaningful conclusion.

Keywords

Windblast

Injury assessment reference values

Nij

Neck injury criteria

INTRODUCTION

Modern generation fighter aircraft has expanded the escape envelope for a fighter aircrew.[1] Windblast is a concern for major injuries and fatalities, with the ejection occurring at very high airspeeds.[2-4] Flying helmet plays a critical role in offering protection to the aircrew during the windblast phase of an ejection.[5] New helmet, before its induction into operational usage, must be tested in simulated windblast conditions for meeting the above qualifying criteria. Toward this, windblast tests were conducted on a newly developed helmet as per the test conditions specified in Mil Std MIL-V-29591/1[6] as a safety certification requirement.

The present windblast testing was conducted on the background of a previous test where significant structural failures were observed on the helmet mask configuration. Design modifications implemented on the helmet and mask, necessitated additional testing to ensure that the modified version would be able to withstand windblast conditions. The test results were analyzed to infer whether the helmet could meet qualifying criteria. The criteria included maintenance of structural integrity and retention of the helmet under windblast conditions. There being no laid down criteria for acceptable windblast neck loads in the Mil Specification, a critical analysis of the neck loads was done in consonance with the neck injury criteria available in the scientific literature.

MATERIAL AND METHODS

Open Jet Windblast test facility mounted with a MB Mk 16 F Ejection Seat was used for conduction of the tests. The manikin used was a large male 95th percentile Hybrid III dummy instrumented for measuring neck loads. The test schedules followed were as per Mil Std MIL-V-29591/1.[6] The test conditions were: Wind speed 600 ± 60 KEAS, rise time of 125 ± 20 ms, time at peak wind velocity of 300 ± 50 ms, and total exposure time of ≥ 3 s. Five windblast tests were conducted with the configurations of seat attitudes, dummy head position, and visors position specified in Table 1.

| S. No. | Seat attitude | Head position | Visor position |

|---|---|---|---|

| Test 1 | Seat aft 25° | Head on | Both outer and inner visors down and locked |

| Test 2 | Seat aft 25° | Head on | Outer visor in raised position, inner visor down and locked |

| Test 3 | Seat aft 45° | Head on | Outer visor in raised position, inner visor down and locked |

| Test 4 | Seat aft 45° | Head rotated 45° port | Both outer and inner visors down and locked |

| Test 5 | Seat aft 25° | Head rotated 45° starboard | Outer visor in raised position, inner visor down and locked |

In each of these tests, the dummy was snuggly fitted with helmet and mask. The visors positions were appropriately adjusted as per the test schedule. A visual inspection and photographic documentation of test articles was carried out before and after each windblast test. The behavior of the test articles during each blast condition was examined by high-speed video cameras. Neck loads in the form of neck compression and extension forces and flexion and extension moments were measured in each test condition.

RESULTS

There were no structural failures in the helmet, visors, and mask hose assembly in any of the test conditions. The helmets including visors and masks were retained with the dummy headform during the entire duration of windblast in all test conditions. Analysis of neck loads in the form of neck compression and tension forces and flexion and extension moments revealed the following:

Neck compression forces at the bottom and top of the neck in all the tests were minimal.

Neck tension forces recorded at the bottom and top of the neck are depicted in Table 2.

Flexion and extension neck moments recorded at the bottom and top of the neck are depicted in Table 3.

| Tests | Force at the bottom of neck (N) | Force at the top of neck (N) | ||||

|---|---|---|---|---|---|---|

| Highest peak (N) | Average sustained peak (N) | Time for which sustained (ms) | Highest Peak (N) | Average Sustained Peak (N) | Time for whichsustained (ms) | |

| Test 1 | 1560 | 1430 | 28 | 1600 | 1444 | 72 |

| Test 2 | 1880 | 1687 | 222 | 1880 | 1682 | 273 |

| Test 3 | 1460 | 1252 | 13 | 1770 | 1427 | 35 |

| Test 4 | 650 | - | - | 680 | - | - |

| Test 5 | 1310 | - | - | 1340 | - | - |

| Test 6 | 1280 | - | - | 1180 | - | - |

| Tests | Flexion moment | Extension moment | ||

|---|---|---|---|---|

| Bottom of neck (Nm) | Top of neck (Nm) | Bottom of neck (Nm) | Top of neck (Nm) | |

| Test 1 | 58 | 3 | 51 | 9.6 |

| Test 2 | 53 | 1.3 | 50 | 12.8 |

| Test 3 | 83 | 13.9 | 40 | 13.9 |

| Test 4 | 51.7 | 8.5 | 8.3 | 11.7 |

| Test 5 | 56 | 16.2 | 37.9 | 13.8 |

| Test 6 | 55.2 | 13.8 | 43.4 | 13.5 |

DISCUSSION

Preliminary analysis of the neck loads revealed that the neck tension and extension forces were high, and the neck compression and flexion forces were substantially low. This was an expected outcome in the force environment of windblast conditions. However, the opinion on whether the recorded values of tension and extension forces were within the acceptable limits created dilemma in aeromedical decision-making, there being no laid down criteria in the Mil Specification. Thus, a critical analysis of neck tension forces was done with the recommended tolerance limits available in the scientific literature.

Neck injury criteria

Various criteria, originally based on automotive criteria, have been recommended in the literature for assessing neck injury risk. Two such criteria, which were considered relevant in the context of the present windblast tests, were taken for analyzing the neck loads. These are given below:

Force duration criteria

The limits for neck tension forces for Hybrid III type adult dummies have been defined as Injury Assessment Reference Values (IARVs) given in Table 5-2, Page 35-36 of AGARD 330.[7] The neck tension limits have also been mentioned in a published article titled “Overview of Ejection Neck Injury Criteria” by Nichols.[8] The recommended tolerance limits are as follows:

| AGARD 330 | Paper by Nichols | ||

|---|---|---|---|

| Duriatin(ms) | Limit(N) | Duriatin(ms) | Limit(N) |

| 0 | 452 | 5 | 3385 |

| 37 | 3561 | 37 | 3385 |

| ≥64 | 1351 | ≥48 | 2001 |

Nij criteria

These criteria recommended by Eppinger et al. take into account the combined effects of axial forces with bending moments.[9] Nij is calculated using the equation listed below where Fint and Mint are normalizing limits for Fz (neck tension) and My (neck extension), respectively.

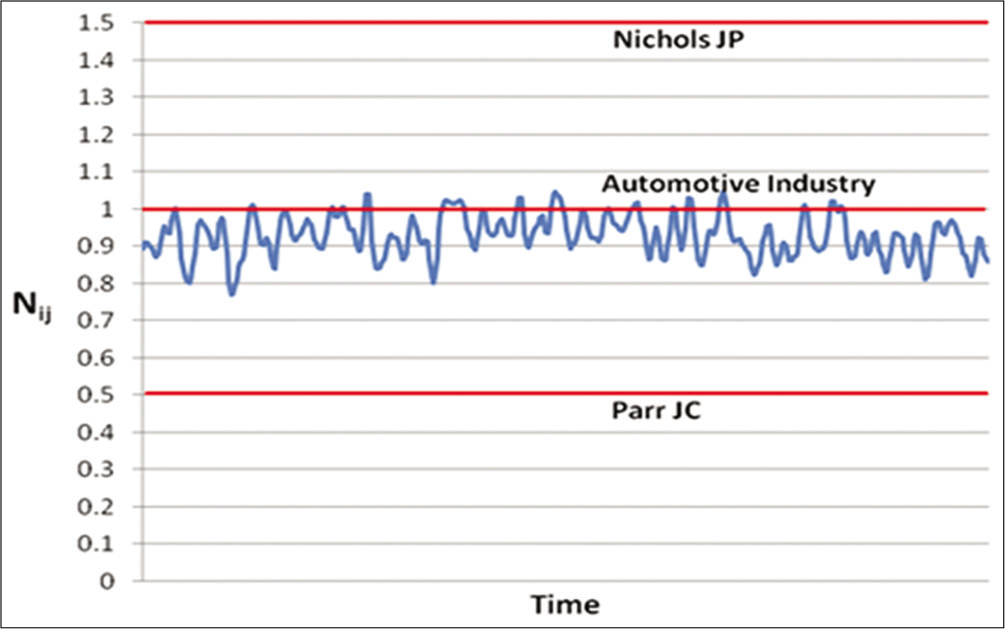

The maximum allowable value of Nij has been defined to be 1.0 for automotive industry.[10] Nichols has proposed a Nij threshold value of 0.5 for the upper neck and 1.5 for the lower neck in ejection testing.[8] More recent paper by Parr et al. (2012) mentions a Nij threshold value of 0.5 for the aviation community.[11]

Analysis of neck loads based on Injury criteria

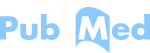

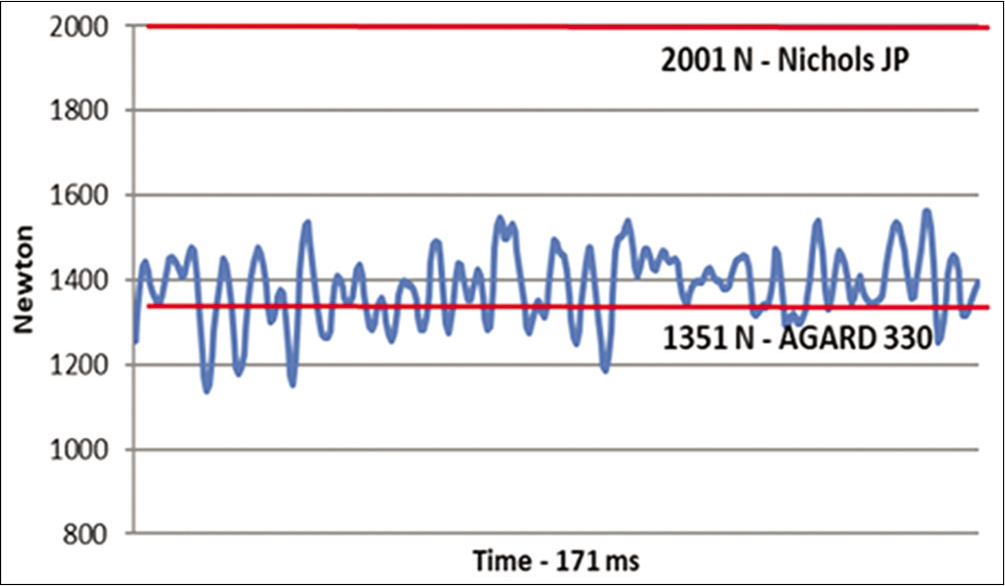

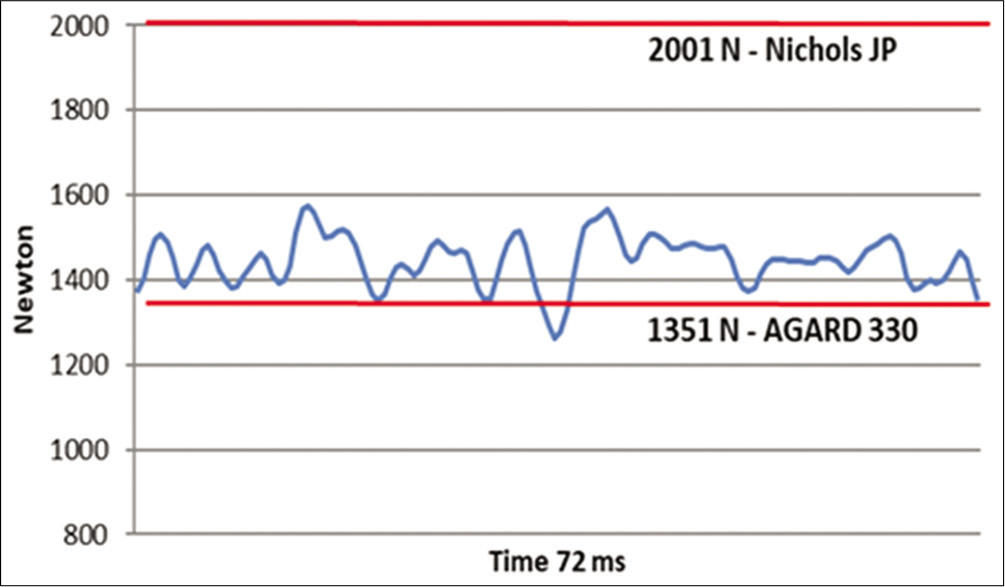

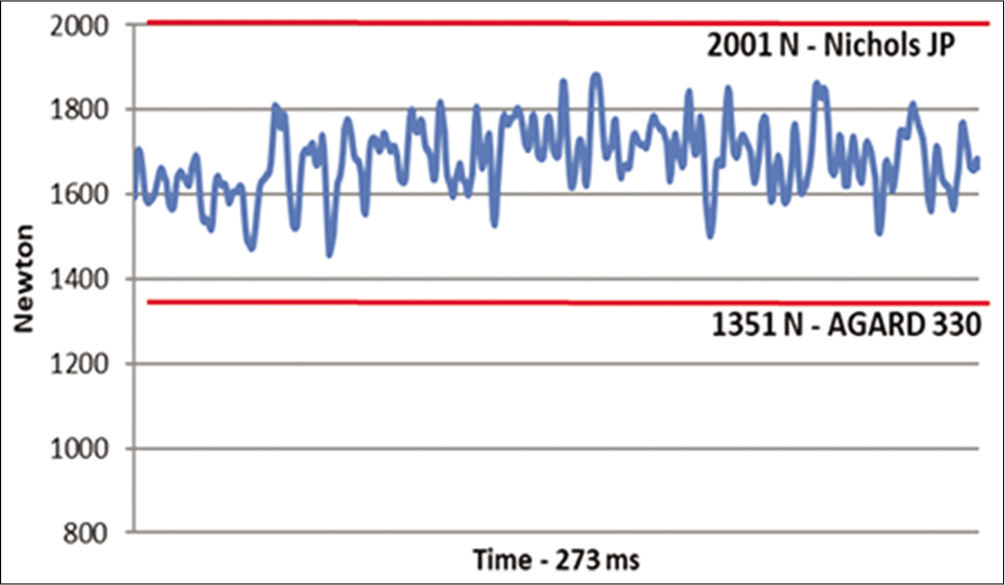

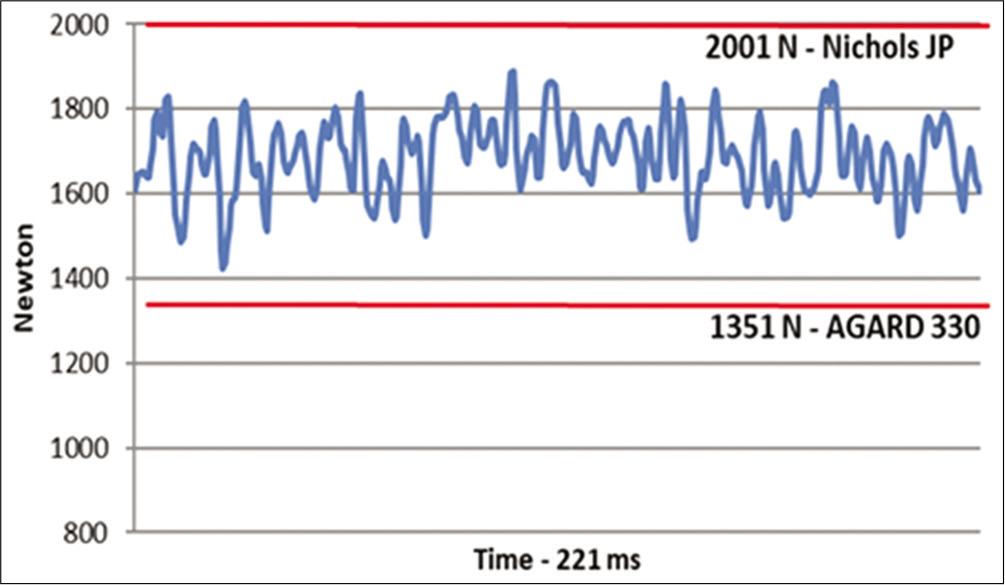

The neck forces recorded in the present tests were analyzed taking the above two criteria into consideration. For the force duration criteria, since the forces were sustained continuously for ≥64 ms, the neck tension forces were compared against the acceptable limits of 1351N (as per AGARD 330) and 2001N (as per Nichols). A graphical representation of the same for top and bottom of the neck for tests 1 and 2 is shown in Figures 1-4.

- Test 1: Neck tension vs time - Bottom of neck.

- Test 1: Neck tension vs time - Top of neck.

- Test 2: Neck tension vs time - Bottom of neck.

- Test 2: Neck tension vs time - Top of neck.

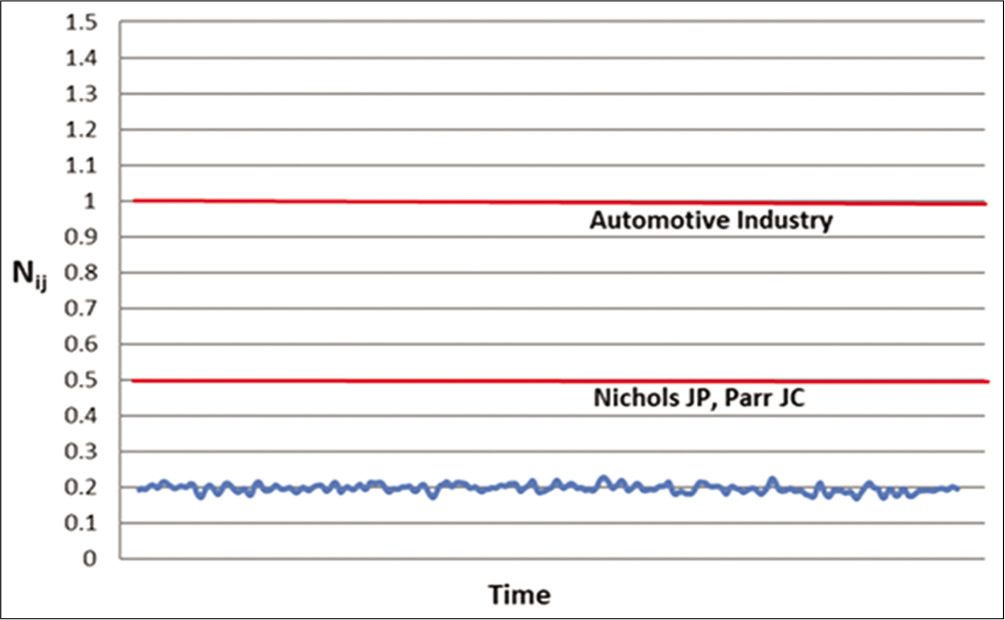

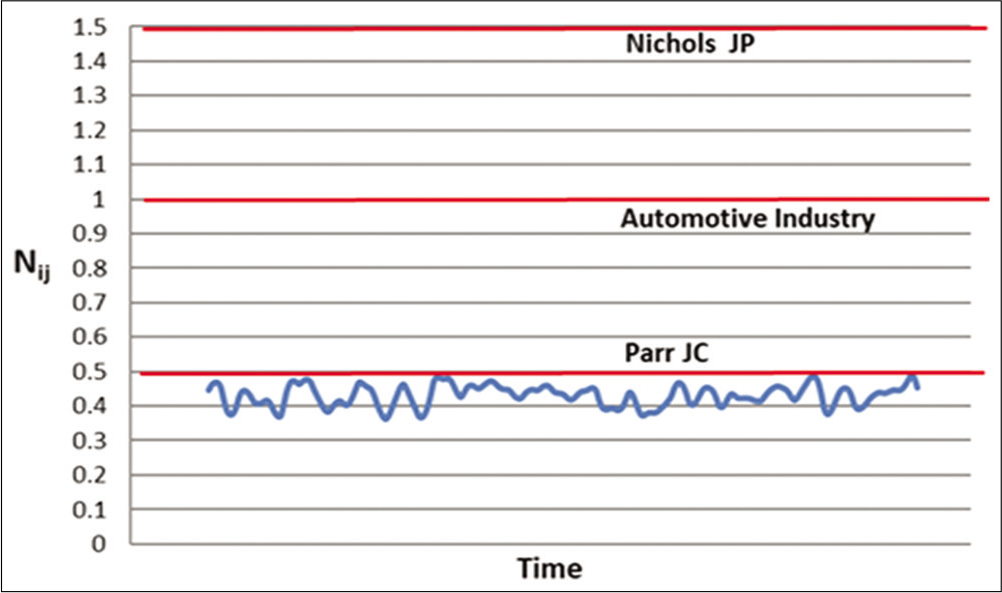

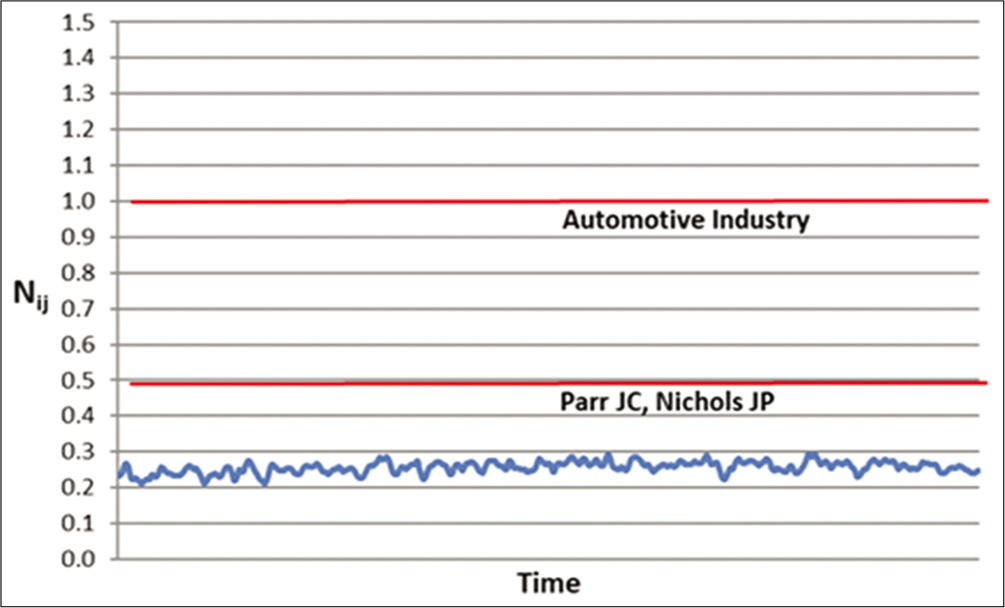

The combined effects of neck tension and extension moments (Nij) were calculated for top and bottom of the neck. The Nij values obtained were compared against the threshold values of 1 for both top and bottom of the neck (Automotive Industry), 0.5 for top and 1.5 for bottom of the neck (Nichols) and 0.5 for both top and bottom of the neck (Parr). A graphical representation of the same for the top and bottom of the neck for tests 1 and 2 is shown in Figures 5-8.

- Test 1: Nij vs time - Top of neck.

- Test 1: Nij vs time - Bottom of neck.

- Test 2: Nij vs time - Top of neck.

- Test 2: Nij vs time - Bottom of neck.

The neck loads of human safety concerns during the windblast are neck tension forces and tension-extension combined effects. The windblast condition most likely to generate high neck loads is when the blast is head on (Test 1 and 2), the worst situation being blast head on with the outer visor in up position (Test 2). Taking the force duration criteria, the neck tension forces at the top of the neck were considered marginal for significant neck injury as per the acceptable limits laid out in AGARD 330 in test 1 (blast head on, both visors down configuration), whereas, this was more than the acceptable limits for significant neck injury at top as well as bottom of the neck for test 2 (blast head on, outer visor in up configuration). The neck tension forces were however within the acceptable limits if we take the force duration criteria proposed by Nichols. For the other test conditions, the neck tension forces were within acceptable limits taking any of the criteria. For neck tension-extension combined effects, the Nij value for the bottom of the neck was more than the acceptable limits as per the limits proposed by Parr and automotive industry for test 2, whereas, this was within the acceptable limits as per the Nij threshold proposed by Nichols. The Nij values were within the acceptable limits for the top and bottom of the neck for other test configurations taking any of the above criteria. Thus, whether the neck forces measured in the present windblast tests would be safe to qualify the helmet for operational usage created dilemma in aeromedical decision making. To make any meaningful conclusion, the standards for acceptable limits for neck loads were revisited.

Critical review of standards

The severities of injuries are classified according to the Abbreviated Injury Scale (AIS) developed by the Association for the Advancement of Automotive Medicine.[12,13] The grades of injury severity associated with AIS classification are given in the following table. Likelihood of a particular grade of AIS is taken into consideration while defining the neck injury criteria.

| AIS | Severity of injury |

|---|---|

| 0 | Not injured |

| 1 | Minor |

| 2 | Moderate |

| 3 | Serious |

| 4 | Severe |

| 5 | Critical |

| 6 | Maximum |

| 7 | Injured but severity not known |

The limits for neck tension forces have been defined in IARVs for Hybrid III type adult dummies in AGARD 330.[7] If an IARV does not exceed the specified limits, then the risk of associated injury will be unlikely. “Unlikely” has been defined as risk levels <5%. AGARD is the advisory group in aerospace research and development, and recommendations by AGARD have been accepted for usage by the international community. On the other hand, neck tension limits mentioned in the paper “Overview of Ejection Neck Injury Criteria” by Nichols correspond to approximately 10% risk of AIS three neck injury, which we consider high.[8] Further, the neck tension limits proposed by Nichols are primarily based on ejection data from a 400 KEAS sled test, and thus, its applicability in predicting safety in high-speed ejection is uncertain. Further, the Joint Service Specification Guide (JSSG) 2010-07, mentions IARV curves for neck tension and compression forces in Figure 10, Page- 38, similar to that given in AGARD-330. The JSSG-2010-7 was published in October 30, 1998, and this document is approved for use by all Departments and Agencies of the Department of Defense (DoD), the USA. JSSG-2010-7 has been reviewed on August 3, 2008, and has been determined to be used in the acquisition.[14]

To the best of our knowledge, the use of Nij has not been evaluated and qualified for the ejection test program. The National Highway Transportation Safety Administration (NHTSA) has accepted the Nij limit of 1.0 for the automotive industry.[10] This corresponds to a value of 22% risk of AIS-3 neck injury. Nichols has proposed a Nij performance limit of 0.5 for the upper neck and 1.5 for the lower neck validating the ejection data from a 400 KEAS sled test.[8] A Nij value of 1.5 corresponds to approximately 43.2% injury risk which is considered substantially high. Parr has proposed a Nij performance limit of 0.5 for usage in the aviation community.[11] We accept the Nij threshold value of 0.5 for both upper and lower neck as proposed by Parr with reasonable confidence for the present windblast testing. This lower limit provides a lower risk of injury, which is essential because of the unique requirement of the military environment. NHTSA’s Nij limit of 1.0 is acceptable in an automotive environment where the first responders will be available shortly after an accident, which is unlikely in an ejection scenario. The pilot would have to escape capture and move to an area from which he could be rescued by a search and rescue team to successfully survive an ejection event.

CONCLUSION

Based on the above discussion, we accepted with reasonable confidence that the IARVs specified in AGARD 330 be taken as the primary criteria for assessing neck tension limits with in present windblast testing. In addition, a Nij limit of 0.5 should be taken as the success criteria. Recently, an aviation-specific, scientifically validated multi-axial neck injury criteria (MANIC) for the assessment of neck loads during the windblast has been recommended for evaluating neck loads during ejection testing. However, within the scope of the present analysis, the application of MANIC could not be undertaken.

Declaration of patient consent

Patient’s consent not required as there are no patients in this study.

Financial support and sponsorship

Nil.

Conflicts of interest

NK Tripathy is the editor of this journal. He does not have any competing interest.

References

- Technical Mini Series in Aerospace Medicine (1st ed). New Delhi: Indian Society of Aerospace Medicine; 2011.

- [Google Scholar]

- Restraint systems and escape from aircraft In: Gradwell DP, Rainford DJ, eds. Ernsting’s Aviation and Space Medicine (5th ed). Florida, USA: CRC Press; 2016. p. :175-86.

- [Google Scholar]

- The effect of acceleration of short duration In: Gillies JA, ed. A Textbook of Aviation Physiology (1st ed). London: Pergamon Press; 1965. p. :746-95.

- [Google Scholar]

- Ejection Seat Capability to Meet Agile Aircraft Requirements In: Wright-Patterson Air Force Base: Air Force Research Laboratory TR-15-09. 2001. p. :121-9.

- [Google Scholar]

- Head injury and protection In: Gradwell DP, Rainford DJ, eds. Ernsting’s Aviation and Space Medicine (5th ed). Florida, United States: CRC Press; 2016. p. :165-74.

- [Google Scholar]

- Visor Assembly, Aviator’s, Seven Wavelength Laser Protection United States: The North Pacific Fisheries Commission Department of Defence; 1997.

- [Google Scholar]

- Anthropomorphic Dummies for Crash and Escape System Testing In: Published by Advisory Group for Aerospace Research and Development (AGARD). Report No. 330. 1996.

- [Google Scholar]

- Overview of Ejection Neck Injury Criteria Reno, Nevada: Proceedings-Annual, SAFE Symposium; 2006. p. :159-71.

- [Google Scholar]

- Development of Improved Injury Criteria for the Assessment of Advanced Automotive Restraint Systems-II Washington, DC: National Highway Traffic Safety Administration; 1999.

- [Google Scholar]

- Supplement: Development of Improved Injury Criteria for the Assessment of Advanced Automotive Restraint Systems-II Washington, DC: National Highway Traffic Safety Administration; 2000.

- [Google Scholar]

- Evaluation of the NIJ Neck Injury Criteria with Human Response Data for Use in Future Research on Helmet Mounted Display Mass Properties. Boston, Massachusetts: Proceedings of the Human Factors and Ergonomics Society 56th Annual Meeting 2012:2070-4.

- [CrossRef] [Google Scholar]

- Abbreviated Injury Scale (Revision) Des Plaines, Illinois: Association for the Advancement of Automotive Medicine; 2008.

- [Google Scholar]

- Development Process of Injury Risk Curves. 2012. Available from: https://www.researchgate.in [Last accessed on 2018 Jan 12]

- [Google Scholar]

- Occupant exposure limit to crash hazard In: Crew Systems Crash Protection Hand Book. Joint Service Specification Guide. United States: Department of Defense; 2010.

- [Google Scholar]