Translate this page into:

In-flight evaluation of cooling efficiency of a modified Environmental Control System in a fighter upgrade aircraft

Abstract

The Environmental Control System (ECS) of a fighter aircraft is designed on the principle of ram air cooling. This limits the capacity of on-board cooling facility especially during low level high speed flying, in turn aggravating the cockpit heat load. An attempt to improve the cooling efficiency of the ECS of a tighter upgrade aircraft was made with some structural and design modifications of the fan and turbo-cooler assembly. This modified fan and turbo-cooler assembly (ModTC) required in-flight evaluation prior to its acceptance by the user. This study presents the findings of the flight trials of the ModTC fitted ac, and its comparison with unmodified fan and turbo-cooler assembly (UnmodTC) fitted aircraft. Wet Bulb Globe Temperature (WBGT) and dry bulb temperature (Tdb) were recorded to evaluate ModTC fitted ECS. A digital Heat Stress Monitor (HSM), for online computation and recording of the cockpit temperature, was installed at the gyro-gun sight inside the cockpit of the aircraft. Cockpit temperature recordings were averaged from 5 minutes of take-off till demist point, i.e. 7 minutes prior to landing, in low level sorties (200m, 0.6 M) with one aircraft fitted with ModTC and another with UnmodTC. The cockpit WBGT and Tdb recorded for ModTC were 29.58°C+0.42 and 27.44°C+0.94, respectively. I n comparison, WBGT and Tdb for UnmodTC were 33.78°C+0.82 and 29.59°C+1.51, respectively. During the trials, the prevailing ambient conditions were 32.6°C/33.4°C Tdb and 29.26°C/30.66°C WBGT for ModTC/UnmodTC sorties, respectively. Comparative analysis of the modified fan and turbo-cooler assembly (ModTC) with the unmodified (UnmodTC) revealed that the modification did not improve the cockpit cooling efficiency. The deterioration in cockpit cooling efficiency was within acceptable limits for the tighter pilot for low level high speed sorties during the prevalent ambient conditions of the flight trials. The reduction in cooling power of the tested ECS, as compared to the unmodified one, could be attributed to the shortcomings in the modification of the design.

Keywords

Fighter aircraft heat load

heat stress monitor (HSM)

The Environmental Control System (ECS) in a fighter aircraft involves ram air cooling as an essential part of its overall design. Its effectiveness is seriously compromised in hot weather conditions during low level flight especially if waiting period on ground is prolonged. Technological advances in modern fighter aircraft with the bubble canopy and the glass cockpit have added to an already existing problem of heat stress on the military aviator. This occurs due to increased heat soak during daytime tactical missions [1], especially low level high speed flights [2, 3] and the advanced on-board avionics [4,5]. Personal protective clothing and metabolic heat [6] further aggravate the problem of heat load. In high performance fighter aircraft, when climatic heat load is further increased by aircraft factors and with limited capacity of onboard cooling systems [7], the cockpit temperatures are higher than the ambient. The high cockpit heat load can seriously compromise the pilot's mission preparedness and flying performance during tactical missions. It is necessary on part of the aircraft designers and human factors specialists that the design of ECS must safeguard and maintain pilots' alertness, mental function and psychomotor coordination during all phases of flight, including operations in extreme environmental conditions [8].

In a normal resting person, heat is lost by the physical mechanisms of radiation, conduction, convection and evaporation of water from the skin and respiratory passages. As ambient temperature increases, the effectiveness of heat loss by radiation, conduction and convection decreases. Instead, heat is then gained by these mechanisms of thermal transfer. In such an environment, the only means of heat dissipation is by sweat evaporation [9]. However, the humidity of the cockpit is likely to increase due to sweat evaporation [10, 11]. If the ECS of the fighter aircraft is not effective in removing humidity content of the cockpit, sweating becomes ineffective and body temperature could rapidly rise beyond acceptable levels [10].

The established physiological end points adversely affecting human performance are elevated core temperature (Tc) of 39 -40°C, heart rate above 180 bpm [12, 13] and body heat storage at 110 kcal/m2[14]. Performance decrement is known to occur much before the end point i.e. at 70-80 kcal/m2 which is about 70% of the maximum heat storage [14, 15, 16, 17].

The ideal method of alleviating heat stress is an effective cockpit ECS. ECS is expected to cater for both the comfort of the operator and the cooling of the cockpit avionics bay. However, several considerations and preconditions like strategic utility, payload and aircraft design have prevented the evolution of an ideal system [7].

Considering the tropical conditions of the Indian subcontinent, it is essential that the aircraft ECS is effective from ground itself. Yet, whenever an older generation fighter aircraft is upgraded, the existing ECS may undergo minimal modifications due to space and design constraints [18], as was the case during a fighter upgrade program where the ECS was refurbished [19]. After a period of time, the user units reported frequent failure of fan and turbo-cooler assembly of the ECS. Modifications were carried out on the fan and turbo-cooler assembly and an assessment on the efficacy of the ECS was mandated.

A Heat Stress Monitor (HSM) was installed in the cockpit to analyze the effect of cabin conditioning of the upgraded fighter aircraft fitted with the modified turbo-cooler of the ECS. This study presents the in-flight evaluation of performance and cooling efficiency of the modified turbo-cooler assembly of ECS of the upgraded fighter aircraft.

Material and Methods

Comparative assessment of the performance of ECS of the upgraded fighter aircraft was undertaken during the monsoon months at an airbase in north India. This period witnesses high humidity and moderately hot ambient conditions. The ideal ambient temperature conditions of 40°C (Tdb) were not available. The trials were carried out at temperatures below this level due to operational constraints (Table 1).

| Parameters | LL - unmodTC | LL-modTC | ML - unmodTC | ML-modTC |

|---|---|---|---|---|

| Tdb(°C) | 33.4 | 32.6 | 29.0 | 28.0 |

| Twb(°C) | 25.4 | 26.0 | 25.6 | 25.0 |

| Tbg(°C) | 47.7 | 39.0 | 36.2 | 29.5 |

| RH(%) | 50 | 57 | 75 | 84 |

| WBGT(°C) | 30.66 | 29.26 | 28.02 | 26.2 |

| FITS (°C) | 35.05 | 38.0 | NA | NA |

| Clouding (Octa) | 4 | 5 | 6 | 7 |

| Time of day (H)Sortie Duration (min): | 14:20 | 13:30 | 13:25 | 09:17 |

| Total | 70 | 70 | 77 | 86 |

| Pre take-off | 23 | 23 | 23 | 31 |

| Post take-off | 47 | 47 | 54 | 55 |

Note: Sorties: LL-Low Level; ML-Mid Level/Step-up TC:

Turbo-cooler assembly of ECS

UnmodTC: Unmodified fan and turbo-cooler in control aircraft ModTC: Modified fan and turbo-cooler in test aircraft NA: Not applicable

Two standard production variants of upgraded fighter aircraft were available for the in-flight trials. The test aircraft was fitted with the modified turbo-cooler (ModTC) and the other aircraft, as control, was fitted with the original 'refurbished' turbo-cooler (UnmodTC).

Keeping in conformity with the overall objective of measuring the heat stress in the cockpit, it was decided to measure the Wet Bulb Globe Temperature Index (WBGT). WBGT is the most accepted integrated measure of heat stress in high heat stress scenario [21, 22]. In military aviation too, the validity and practicality of WBGT are well established [2,23]. The relevant sortie-related data was obtained from the aircraft flight data recorder l FDR). This included the time of start up, canopy closure, warm-up, take-off, landing, and other parameters during different phases of the sortie including the speed and altitude.

The sortie profile for the trials included two l ow and mid level sorties each by both the test and the control aircraft. The acceptable limits of thermal load in cockpit for test, as per manufacturer's >pecifications, were dry bulb temperature (Tdb) of 25-35°C in the cockpit while flying at an operative ambient temperature (OAT) of 40°C at 200m and at 0.6 Mach (M). The acceptable limit of WBGT is less than 32°C for a pilot in the cockpit of a fighter aircraft [23]. Comparative performance of modified 😮 unmodified fan and turbo-cooler assembly during Low Level (LL) sorties, akin to low level escort -ussions, and mid level (ML) or step-up sorties, akin to Combat Air Patrol, was undertaken to assess the effectiveness of the ECS. Temperature settings during the sortie for cabin control were kept at 'auto' to maintain cockpit Tdb of 25°C. Since only one HSM was used and independent instrumentation was not available for both test and control aircraft, type sorties flown during similar ambient conditions were considered for comparison of cooling efficiency and performance of ECS.

The recording of cockpit thermal parameters was undertaken with a HSM. HSM is designed and developed for assessment of high heat load conditions, both in laboratory conditions [3] and inflight or field trials [2]. This is a microprocessor controlled, battery-operated device. Its advantages are availability of tripod sensors to record thermal data viz. dry bulb temperature (Tdb), wet bulb temperature (Twb), radiant temperature (Tbg); online computation of WBGT with running time stamp at an interval of 1 minute each [24]; and facility for analysis of stored thermal data against sortie profile as per FDR. The recorded heat stress parameters and the WBGT index indicate the extent of heat soak that aircraft factors induce during the whole sortie including the waiting-in period.

HSM was placed inside the cockpit after consultation with the aircrew participating in the in-flight trials. It was ensured that the HSM neither obstructed the vision inside or outside the cockpit nor hindered the operation of any of the controls inside the cockpit. HSM was firmly fixed in its chosen location, prior to each in-flight trial sortie, with a suitably designed clamp. The location was such that it would allow free flow of air around the thermal sensors (Fig 1).

- Heat stress monitor mounted in the cockpit

Prior to the planned sortie for heat stress data collection, the HSM battery was charged overnight and previously stored data, if any, was deleted in the morning prior to use. Then the settings for date, time and heat stress parameter recording interval every 1 minute was done. The cup of the wet bulb thermometer was filled with distilled water 30 minutes prior to commencing the temperature recording. Thereafter, the HSM was tested for calibration by recording the ambient thermal data in shade, for 5 minutes and comparing it with the readings of a sling psychrometer, without rotating it, as per standard practice [2].

After this the HSM with its sensor tripod was firmly secured at its selected place in the cockpit (Fig 1). The water level in the cup of the wet bulb thermometer was rechecked. The tightness of the screw of the tripod sensors' data cable with the main console of HSM was rechecked. Thereafter the HSM was switched on to 'store' mode for starting the data recording; and time of switching it on was noted. Immediately after the sortie, the stored data from the HSM was downloaded to a compatible personal computer. This was to facilitate the analysis of thermal data including average temperature, maximum temperature, and time at maximum temperature and data during various phases of the sortie. The HSM recording commenced 5 minutes before the pilot sat in the cockpit to strap up prior to initiating the start up procedure and it was terminated after the sortie.

In addition, subjective feedback from the pilots was obtained immediately after the sortie.

Results

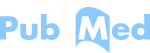

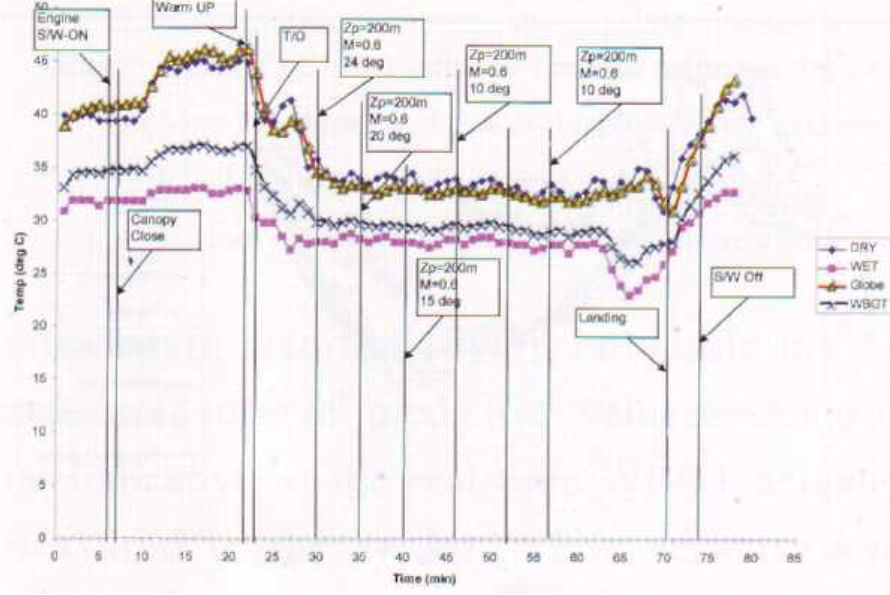

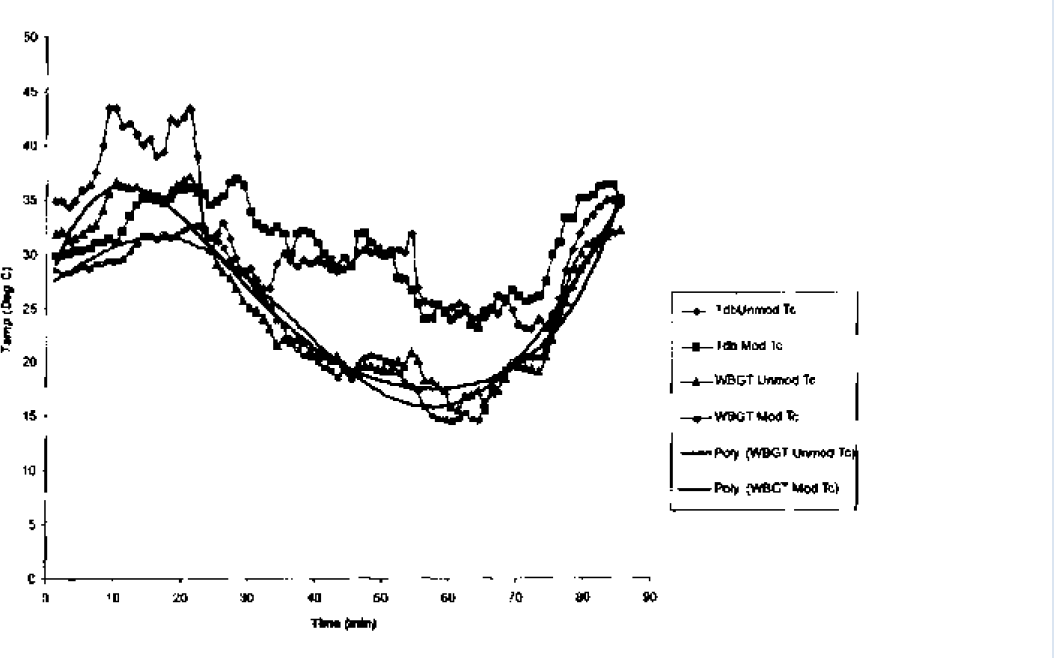

The data of WBGT during low level sortie for both the test and the control aircraft is shown at Table 2. Comparison of different events during the sorties during comparable ambient conditions, prevalent during similar lime of the day (1330-1430 H), revealed that the maximum heat stress during the low level sortie preceded lake-offal the end of taxiing at 17"' minute for the test aircraft and at the time of canopy closure before taxiing at 9"' minute for the control aircraft (Fig 2, 3)

| Parameter | ECS Type | Pre take-off | After Take-off | 5 min after take-off | 5 min altertake-off till demist at 7 min before landing |

|---|---|---|---|---|---|

| WBGTmax( °C) | UnmodTC | 41.4 | 36.2 | 32.9 | 31.1 |

| ModTC | 37.2 | 33.3 | 30.9 | 30.9 | |

| Time ot'WBGTmax | UnmodTC | 9lhmin | 24lh nun | 68"' min | 3 1" min |

| ModTC | 17"' min | 24'" min | 29"'mm | 29"'min | |

| WBGTavg( °C) | UnmodTC | 39.12+1.61 | 28.17 + 2.18 | 27.92+1.75 | 27.44 + 0.94 |

| ModTC | 35.7+1.19 | 29.48+1.31 | 29.18+1.00 | 29.58 + 0.42 | |

| Tdbavg( °C) | UnmodTC | 45.8 + 2.30 | 31.02 + 3.27 | 30.54 + 3.04 | 29.59+ 1.51 |

| ModTC | 42.35+2.44 | 34.4 + 2.19 | 33.72 + 2.19 | 33.78 + 0.82 |

Note: UnmodTC: Unmodified fan and turbo-cooler assembly in control aircraft ModTC: Modified fan and turbo -cooler assembly in test aircraft

- Heat stress parameters in test aircraft during low level sortie

- Heat stress parameters in control aircraft during low level sortie

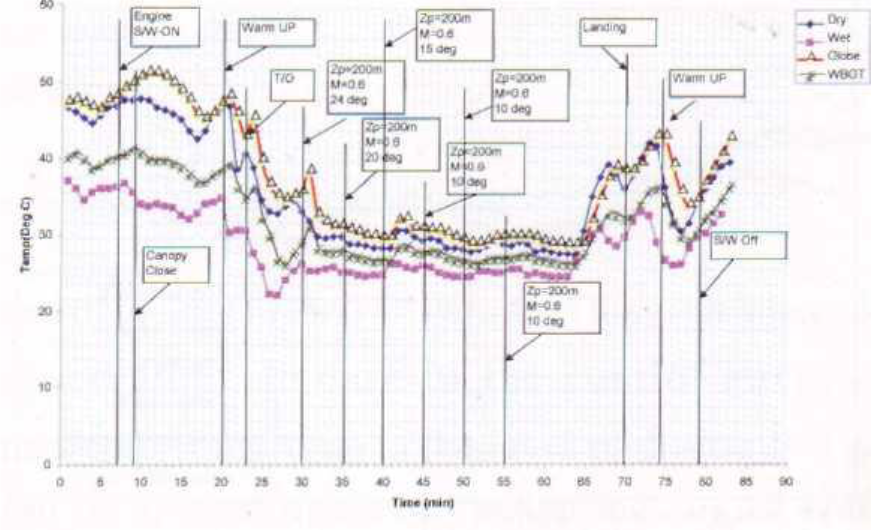

The WBGT data during the mid level sortie for both the test and the control aircraft are shown in Table 3. The WBGT data for both the aircraft were found to be comparable (Fig 4, 5). Table 4 presents the thermal data for both low and mid level sorties for both the test and the control aircraft. This includes Tdb, Twb, Tbg and WBGT.

| Parameter | ECS Type | Pre take-off | After Take-off | 5 min after take- off | 5 min after take-off till demist at 7 min before landing |

|---|---|---|---|---|---|

| WBGTmax(°C) | UnmodTC | 37.2 | 30.7 | 25.8 | 25.8 |

| ModTC | 32.8 | 32.2 | 32.2 | 24.8 | |

| Time of WBGTmax | UnmodTC | 21"' min | 24l"min | 29"' min | 29"' min |

| ModTC | 22'"' min | 85"' min | 85"' min | 76"' min | |

| WBGTavg(°C) | UnmodTC | 34.63 + 1.96 | 20.91+3.47 | 20.13 + 2.51 | 20.10+2.46 |

| ModTC | 30.21 + 1.67 | 21.41+5.21 | 21.12 + 5.37 | 19.18 + 3.16 | |

| Tdbavg(°C) | UnmodTC | 39.33 + 3.39 | 27.66 + 2.71 | 27.28 + 2.53 | 27.73 + 2.35 |

| ModTC | 33.75 + 2.38 | 29.42 + 3.85 | 29.17 + 3.95 | 28.16 + 3.23 |

Note: UnmodTC: Unmodified fan and turbo-cooler assembly in control aircraft ModTC: Modified fan and turbo-cooler assembly in test aircraft

- Comparative heat stress parameters in test and control aircraft during low level sortie

- Comparative heat stress parameters in test and control aircraft during mid level/step-up sortie

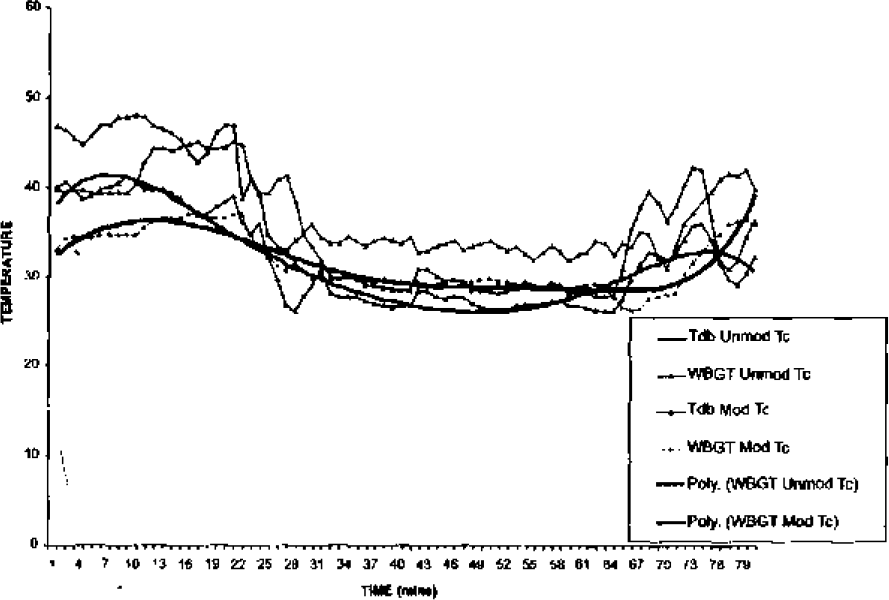

Comparison of the cockpit thermal stress indices for both the sorties revealed that the cockpit thermal stress was higher during the low level sorties [4, 5] for both the test and the control aircraft (Table 4). The thermal stress conditions in the cockpit during low level sorties, from 5 minutes after take-off till demist point (7 minutes prior to landing) revealed that average WBGT was 29.58°C and27.44°C for the test and the control aircraft, respectively. The corresponding OAT was 32.6°C and 33.4°C, respectively. The cockpit thermal stress during the midlevel sorties was comparable during similar ambient conditions with OAT of 28°C and 29°C, for the test and the control aircraft, respectively.

It was also found that prior lo take-off. the thermal stress was more inside the cockpit of the control aircraft (Table 2 and 3); but after takeoff there was reversal of performance of the ECS, where the test aircraft showed higher heat stress in low level sorties (Table 2). Thus, it is evident that cockpit cooling of the test aircraft was inferior to that of the control aircraft. The desired temperature to be maintained in the cockpit as part of test protocol was 25°C (Table 2) which was not possible even in the comfortable ambient of 32.6°C (Tables 3 and 4).This is an important observation since the cockpit temperature was recorded when the prevailing OAT was 32.6°C (Tdb), and not the ideal test condition of 40°C (Tdb) (Tables 2 and 4). However, from 5 minutes after take-off till the time of landing, the maximum recorded WBGT was 30.9°C for the test aircraft. This was within the acceptable limits of thermal comfort, i.e. WBGT below 32°C, in the aircraft, as per the test protocol.

Discussion

Heat stress parameters viz. Tdb, Twb, Tbg and WBGT were found to increase in both types of aircraft during low level and mid level/step-up sorties.

Low level flying is an event that is carefully planned and permitted at flying bases when the prevalent OAT is less than 40°C. High humidity confers greater heat stress at lower OAT. Heat balance is affected by all three parameters: Tdb, Twb and Tbg; of which only one, OAT or Tdb has been considered so far. It may be suggested, after careful deliberation, that a more realistic approach would be an index that gives due importance to humidity and radiant heat both, is easy to calculate and does not consider air velocity since likely cockpit conditions being judged [6] fulfill these criterion [2,20].

Fighter Index of Thermal Stress (FITS) [23] was calculated (Table 1) from ambient conditions (OAT/Tdb) and the psychrometric wet bulb

The maximum heat stress during low level sortie, in terms of WBGT was in the 9th minute in the control aircraft. This coincided with the time of canopy closure whereas the maximum heat stress in the test aircraft just preceded take-off at the end of stress recorded was 41.4°C (WBGT), at the 9"' minute as compared to 37.2°C in the 17"' minute in test aircraft.

The pilots reported perceptible difference in comfort levels during the low level sorties but not during the mid level ones. There was a difference in the cooling performance of ECS during the low level sorties. The qualitative feedback about subjective sensation of comfort corroborated with the quantitative data obtained (Table 4).

There was a noticeable drop in the efficiency of maintaining the desired temperature during low level sorties, attributed to differences in aerodynamic heating, as compared to mid level in the control aircraft. However, it was still adequate and comfortable for the pilot. The overall performance of the ECS was satisfactory especially after getting airborne. The performance of the ECS of the test aircraft was similar except when the two types of turbo-coolers were being compared for their performance at low levels.

Test points at 200m at 0.6M with an OAT of approximately 33-34°C required the pilot to change the cockpit temperature settings manually from 24°C to 10°C. Even at the lowest setting of 10°C, the cockpit environment of the test aircraft was perceived to be uncomfortable with moderate sweating. Though subjective, this indicated unsatisfactory performance of the modified ECS and hence was considered unacceptable.

Although the ECS of both the aircraft were able to maintain cockpit temperatures below the caution zone, measured parameters indicated a better performance of the control aircraft during low level sorties. Average WBGT of test aircraft was almost 3°C higher at 29.5°C when compared to the control aircraft in low level sorties. 35 readings of WBGT were taken into consideration, from 5 minutes oftake-offtill 7 minutes prior to landing at demist point, to allow an adequately correct functional assessment of the turbo-coolers in the fighter aircraft.

At an OAT of 32.6°C, cockpit average WBGT was more in case of the control aircraft. Thus, the ECS of the control aircraft evidently was found to be 'quick enough' to control the thermal environment of the cockpit, with maximum heat approximately 2.4°C less than the limit that is advised for human thermal comfort (WBGT 32°C). It is also mentionable that Tdb was only 1.2°C less than the desirable upper limit (Tdb 35°C). At an OAT of 40°C, which was the ideal specification, both WBGT and Tdb limits are likely to be exceeded. This was a clear indicator that performance of modification carried out in the fan and turbo-cooler assembly of ECS in the test aircraft was inferior to that of control at low level and thus did not meet the specifications. At mid levels, the performance of both test and control ECS was similar.

In an earlier study [19] complete sortie duration was considered to compare the cooling efficiency and performance of two different ECS during low level sorties in similar aircraft type. The values of average WBGT for both the test and control aircraft in the present study are 31.5°C and 31.7°C, respectively for the complete sortie duration. Since pre- and post take-off are two separate phases as far as the performance requirement of ECS is concerned; WBGT was studied for pre- and post-take-off phases, separately. The average WBGT for test and control aircraft during pre take-off phase was 35.7°C and 39.12°C respectively and during post take-off phase was 29.48°C and 28.17°C. This indicated an immediate reduction in heat stress after take-off which continued to reduce till the aircraft leveled off at 200 m. Interestingly during the pre take-off phase lasting about 23 minutes, the test aircraft had recorded comparatively lower heat stress; while in the post take-off phase, it was the ECS of the control aircraft that fared better in terms of average WBGT. Further analysis of the post take-off phase after about 5 minutes in flight, revealed a comparative cockpit WBGT of 29.18°C7 27.92°C for test/control aircraft. This was the cockpit heat stress index between 29"' minute (5 minutes after take-off) till 70"1 minute when the aircraft landed.

During the sorties, the pilots had switched on the 'demist' 7 minutes prior to landing, to prevent condensation on the canopy, as per the protocol followed. Since the turbo-cooler performance cannot be judged fairly when 'demist' is operant, it was deemed appropriate that the recordings of the last 7 minute prior to landing ought not to be considered when commenting on ECS efficiency. Hence, cockpit WBGT was averaged from 5 minutes of take-off till demist point. The comparisons of the test and control aircraft finally were average WBGT values of29.58°C+0.42 and 27.44°C+0.94, respectively.

With prevailing ambient conditions of OAT 33.4°C and WBGT 30.66°C during low level sorties, cockpit average WBGT, from 5 minutes of takeoff till 7 minutes before landing, was found to be lower in the control aircraft at 27.44°C while it was 29.26°C for the test aircraft when the prevailing ambient conditions were OAT of 32.6°C and WBGT of29.26°C. Evidently under more stressful ambient conditions, control aircraft with its original fan and turbo-cooler assembly would perform better to lower the cockpit heat stress more efficiently. The modified ECS was decidedly poorer in performance when compared to the earlier ECS without modification.

Conclusion

Specification against which the provided fan and turbo-cooler assembly of the ECS was being tested was maintaining the cockpit temperature WBGT) to less than 32°C at an OAT of 40°C at an altitude of 200 m at 0.6M. This could not be achieved, as the prevailing OAT was less than 3"C. Assessment of the modified fan and turbo cooler assembly of the ECS was done by studying comparative performance at Low Level sorties (for the role of Low Level Escort Missions) and mid-level (ML)/ step-up sorties (for the role of Combat Air Patrol).

The thermal stress in the cockpit was maintained within satisfactory limits. The comfort level in the cockpit maintained by the control was better than that of the test ECS. The loss in cooling efficiency due to the modification was within acceptable limits as it was able to maintain the WBGT well below 32°C. The comparison of the thermal stress indices indicated that the control ECS was able to maintain the WBGT in the cockpit at almost 3°C lower than the test.

It could be inferred that there was a loss in the cooling efficiency of the fan and turbo-cooler assembly of the ECS due to the modification.

Acknowledgement

The authors gratefully acknowledge the encouragement, guidance and advice offered by Air Cmde Pankaj Tyagi VSM, Commandant IAM, IAF, and Bangalore during the conduct of the in-flight trials. The authors also acknowledge the contribution of the in-flight trial team consisting of Wg Cdr R Joshi, Wg Cdr S Jaishankar, Sqn Ldr BN Athreya, Sqn Ldr MKA Shakir and the ground crew who provided whole-hearted unstinted support throughout the trials.

References

- In flight thermal data from Harrier. Phantom, Buccaneer, Gazelle and Scout ac. RAF Institute of Aviation Medicine, Flying Personnel Research Committee FPRC/1354.

- [Google Scholar]

- Assessment of cabin conditioning system in a fighter ac. Ind J Aerospace Med. 2001;45(2):37-46.

- [Google Scholar]

- The thermal environment and human heat exchange In: Ernsting J, King P, eds. Aviation Medicine (3" Ed). London: Butterworths; 1999. p. :192-202.

- [Google Scholar]

- Thermal Stress. In: DeHart RL, Davis RA, eds. Fundamentals of Aerospace Medicine (2 ' Ed). Baltimore: Williams & Wilkens; 1996. p. :399-422.

- [Google Scholar]

- Relationships between ambient, cockpit and pilot temperatures during routine air operations. Aviat Space Environ Med. 1978;49:5-13.

- [Google Scholar]

- Physiological requirements for design of environmental control systems: Control of heat stress in high performance ac. ASME Pamphlet 78-ENAS-22 1978:8.

- [Google Scholar]

- Upper thermal tolerance limits for unimpaired mental performance. Aerospace Med. 1965;36:960-965.

- [Google Scholar]

- Determination of heat susceptibility and heat tolerance-A new index. J AeromedSoc of India. 1968;11:6-14.

- [Google Scholar]

- Metabolic effects of short exposure to a hot environment in man. Annals of human Bio. 1975;2:41.

- [Google Scholar]

- Human cardiovascular adjustments to exercise and stress. Physio Rev. 1974;54:75-79.

- [Google Scholar]

- Tolerance of hot and wet environments by resting man. J Appl Physiol. 1965;20:271-277.

- [Google Scholar]

- Effects of precooling on heat tolerance and estimation of precooling requirements. J AeromedSoc of India. 1969;12:25-28.

- [Google Scholar]

- A unified system for evaluation and selection of heat stress candidates. J Appl Physio. 1961;16(1):144-152.

- [Google Scholar]

- Human tolerance for high temperature aircraft environments. J AvMed. 1954;25:515-520.

- [Google Scholar]

- Human performance at elevated environmental temperature. Aerospace Med. 1973;44:747-749.

- [Google Scholar]

- Thermal problems in military air operations. AGARD conference proceedings No. 642. Neuillysur Seine 1976:81-85.

- [Google Scholar]

- In-flight thermal data recording from IAF aircraft. Aviation Medicine. 1986;30:33-37.

- [Google Scholar]

- Control of heat casualties at military training centers. Arch Indust Health. 1957;16:203-216.

- [Google Scholar]

- Occupational Safety and Health Administration U.S. Dept of Labor OSHATechnical Manual Section III Chapter4 Heat stress. Available at http://www.osha-sle.RQv/dts/osta/otn/otm.toe.html (accessed on 11 Mar 07)

- [Google Scholar]

- 'Fighter Index of Thermal Stress (FITS) Guidance for hot weather aircraft operations' Aviat Space and Environ Med. 1979;50:639-642.

- [Google Scholar]

- RSS-211 D Heat Stress Monitor Reuter Stokes Inc. Manufacturer's specification, Canada.

- [Google Scholar]