Translate this page into:

Design of Proposed 3-D Solid Model of Dilution Demand Oxygen Regulator for High Altitude Para Jumper

Abstract

Defence Bio-Engineering & Eiectromedical Laboratory (DEBEL) is carrying out the design and development of a suitable breathing regulator for adequate protection against hypoxia up to 30,000 ft. A pneumatic circuit to realize the required performance has been conceptualised. Experiments have been carried out to fix certain parameters like nozzle diameter for oxygen flow and aneroid expansion with respect to altitude to determine port size for air dilution. With these inputs 3D solid modelling of the system was carried out keeping in mind the constraints of shape, size, volume, weight and operational requirements. I-DEAS software was used for modelling the regulator. The regulator consists of a pilot bleed operated supply and suction diaphragm arrangement which will supply breathing gas on demand. The dilution is achieved by sucking ambient air through dilution port when the reduction in pressure is caused by high pressure oxygen passing through the nozzle. The amount of dilution is controlled by constricting the dilution port by an altitude sensitive aneroid. At ground level a maximum dilution of 50% was achieved. The regulator is also provided with a manual selection switch to select pure/100% oxygen as and when required. The paper describes the function of pneumatic circuit designed to implement the functional requirements and experiments carried out to determine important parameters and design of 3D solid model for dilution demand regulator.

Keywords

Hypoxia

Demand regulator

Injection dilution

Aneroid

Hypoxia, the condition caused by the insufficient oxygenation of blood, is an ever present danger for high altitude Para jumper. Ascent to higher altitudes cause a reduction in barometric pressure, resulting in fall in the partial pressure of oxygen in the blood and the body tissues get starved of oxygen leading to hypoxia [1]. The alveolar oxygen tension must be kept at the minimum allowable value of 103 mm of Hg to prevent hypoxia. This can be achieved by progressively increasing the concentration of oxygen in the inspired gas with increasing altitude [2,3]. However, this is possible only up to 34,000 ft. Above this altitude, the alveolar oxygen tension falls even if 100% oxygen is inhaled. On the other hand, inhalation of 100% of oxygen at altitudes below 13,000 ft for prolonged amount of time is not desirable. The maximum permissible concentration of oxygen at ground level is only 60% [4], Further, use of pure oxygen will deplete the supply in the cylinder at a faster rate and will decrease the breathing time. Hence the use of a breathing regulator which supplies oxygen in correct proportion and quantity with respect to altitude is highly recommended.

The proposed breathing regulator (dilution demand regulator) is designed to meet the requirements of high altitude para jumper. Its demand function prevents the wastage of oxygen during exhalation. The regulator dilutes pure oxygen with ambient air and maintains the correct proportion of oxygen in the breathing gas depending on the altitude. These features economises the source and increases the breathing time. The regulator design meets the constraints of size, weight and volume and is rugged to withstand day to day handling by the user.

Methods

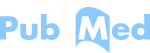

Design of Concept Schematic. The schematic of the pneumatic circuit of the dilution demand regulator which is conceptualised to realise the functions of the regulator is shown in Fig. 1. It exploits the principle of outlet flow control using pilot bleed, injection dilution, and expansion of aneroid with respect to altitude [5].

The demand regulator incorporates injection dilution technique to dilute pure oxygen with atmospheric air. In this technique, the ambient air is sucked in by the negative pressure created when pure oxygen flows through a dilution nozzle. The size of the opening through which the ambient air comes in is controlled by an altitude sensitive aneroid.

The unit has provision for giving two inputs, one from the man mounted oxygen cylinder (which the para jumper carries with him) and one from the pre breather console. The input connectors are of Double Shut off Quick Disconnect type, which facilitates easy connection and disconnection. The double shut off mechanism cuts off both sides during disconnection thus preventing the entry of any foreign particles such as dust in the system.

The regulator is supplied with pure oxygen at the inlet ports (PI or P2) at a regulated pressure of 35 + 10 psi. The pilot pressure tapped through the metered calibration constriction (8) acts on the larger area of the supply chamber diaphragm (1) as compared to the smaller area on which the inlet pressure is acting. The supply diaphragm thus remains pressed against its seat. The pilot pressure is prevented from bleeding as the suction diaphragm (4) keeps the nozzle/bleed port(5) closed under the action of spring (10). The supply diaphragm will lift and output will be established only when the pressure in pilot chamber is bled.

During inhalation, pressure drops in demand chamber (9). The suction diaphragm lifts against the spring loaded valve causing the pressure in pilot chamber to bleed. The pressure in the pilot chamber falls and supply diaphragm is opened thereby allowing the main supply to pass through dilution nozzle(3) and to output port (P4). As soon as the lung pressure balances the mask pressure, pressure in the demand chamber gets balanced. The suction diaphragm closes the bleed port under the action of spring (11). The pressure in pilot chamber rises and the supply diaphragm is pushed back to its seat, turning off the output. The breathing resistance is determined by the spring in the suction chamber. The adjusting screw (10) is adjusted so as to get a breathing resistance of less than 2 mm of Hg. The volume of pilot chamber determines the response time of the regulator. Smaller the volume better is the response.

Schematic of Dilutor Demand Oxygen Regulator

When the output from supply chamber passes through the dilution nozzle (3), suction pressure is created at the throat of the nozzle which causes the atmospheric air to be sucked in through the port P3. The ambient air and oxygen gets mixed in the demand chamber and goes to the mask. The dilution aneroid (2) expands with altitude, thus controlling the flow of ambient air that mixes with the oxygen. This will ensure appropriate concentration of oxygen in the breathing gas. At 28,000 feet, the aneroid completely closes the air port (P3), thus, providing an output of 100% oxygen.

The regulator is also provided with a pressure compensatory drain valve which keeps the output pressure within safe limits and a manual 100% oxygen seletion switch to select pure oxygen as and when required.

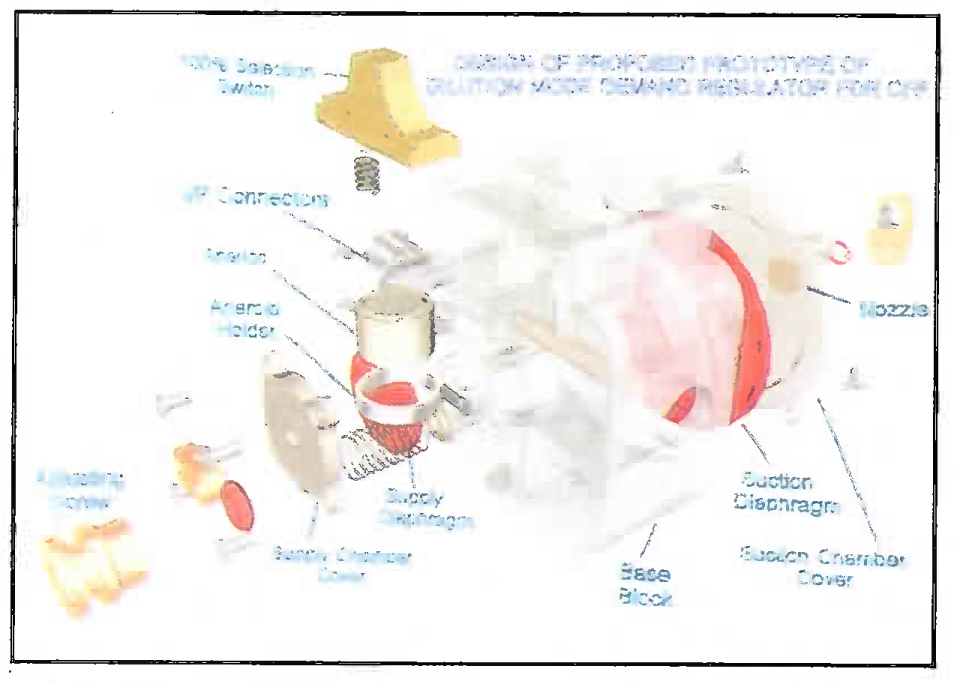

Experimental Design. Theoretical design calculations were done to determine various parameters and the same were validated through experiments. Experimental set up was made to measure the flow and pressure of oxygen at inlet and air/oxygen mixture at outlet of the regulator. A special pressure transducer was fitted at the air inlet port to measure the negative pressure created at the nozzle exit. Experiments were carried out with different nozzle diameters (1, 1.25, 1.5 and 2 mm), the flow at the inlet of the regulator was adjusted in such a way that outlet flow is 10, 15, 20 and 25 1pm. The difference between the two flow meter readings gives the ambient air flow which gets mixed with the oxygen. Based on inlet oxygen flow and ambient air flow, the air/oxygen ratio and percentage of oxygen in the outlet gas was calcualted.

The maximum flow of oxygen, which the nozzle can handle, was also measured. These experiments were repeated for different input pressure (1,1.5,2,2.5,3,4,5 bar).

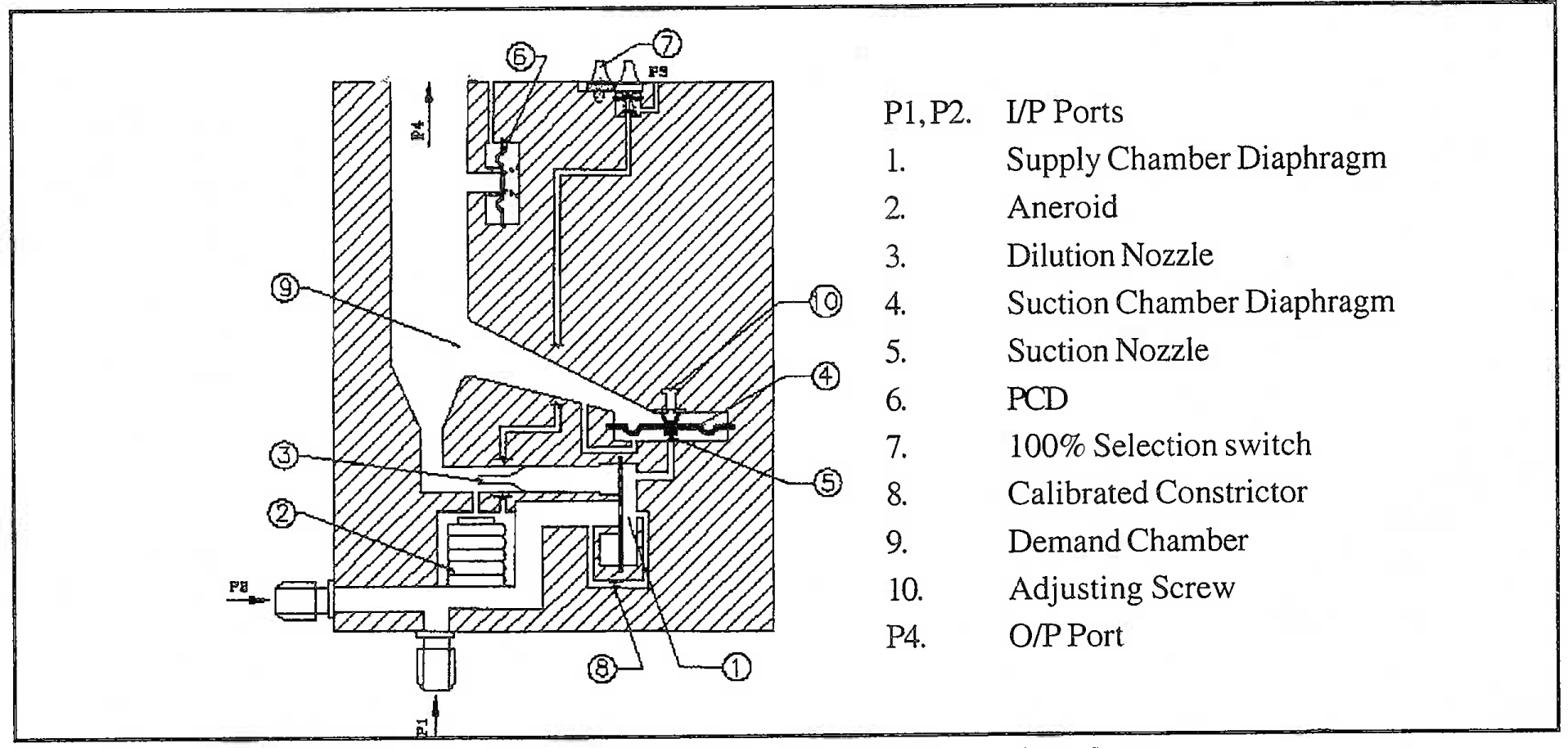

Design of 3D solid model. The emperical data was used in the design of various individual components and 3D solid model of the regulator was created. The model is shown in Fig. 2. I-DEAS software was used extensively in its design. Concurrent design aproach is followed in the design; the various individual components are designed in I-DEAS Master Modeller and are then assembled in I-DEAS Master Assembly. The assembly is checked for interference and fitment and the design is optimised for weight and size. The model formed a base for further downstream applications such as 2D drafting, mass property calculations and tolerance analysis. This resulted in a compact system with envelope dimensions of approximately 60 X 60 X 35 mm and weighing about 400 g.

Proposed 3d Solid Model Of Dilution Demand Oxygen Regulator

Results and Discussion

The successful and efficient working of the regulator depends on the estimation of certain critical parameters such as nozzle diameter and diameter of ambient air inlet port. The flow through the nozzles and other conduits were analysed using compressible fluid flow equations. For the sake of simplicity, the flow through the nozzle is assumed to be reversible adiabatic (isentropic). It is also assumed that the flow is frictionless and under steady state conditions.

The nozzle throat diameter is calculated using the equation [6].

Variation of Air/O2 with Nozle diameter and O/P flow

Where,

= mass flow rate

A2 = area of cross section at nozzle throat

C0 = coefficient of discharge

P1 &P2 = pressure at nozzle inlet and outlet

R0 = gas constant

T1 = temperature at nozzle inlet

Cp = specific heat at constant pressure

γ = ratio of specific heats

And it computes to 1.25 mm for 251pm flow, from the equation

Where,

= mass flow rate

Aa = area of cross section of air inlet port

Ca coefficient of discharge

ΔP pressure gradient across air inlet port

ρa =density of air

The ambient air inlet port diameter computes to 3.5 mm, for 50% dilution at ground level and is kept at 5 mm to keep the flow resistance to a minimum.

Experiments were conducted with nozzles of different diameters, by changing the flow and inlet pressure. The results are plotted in Fig. 3 and Fig. 4. Fig 3 shows the variation of Air/O2 in the breathing gas with respect to nozzle diameter and output flow. It can be seen that for a particular outlet flow, the Air/O2 ratio varies inversely with nozzle diameter. Similarly, for a particular nozzle diameter, the Air/O2 ratio increases proportionally with outlet flow. Fig. 4 shows the variation of maximum average flow with nozzle diameters at various inlet pressures. From the plot, it can be seen that, the maximum average flow varies inversely with nozzle diameter for a particular inlet pressure. As the inlet pressure increases, flow also increases. The maximum flow that can be handled by the nozzle is important since after 28,000 ft the ambient air port will be closed and the nozzle must be capable of meeting the maximum flow requirements.

Variation of O/P flow with Nozzle diameter at various input pressures

Thus a trade off is made between the outlet flow and Air/O2 ratio, and a nozzle of suitable diameter is chosen. From Fig. 3 it can be seen that in order to handle 251pm flow while giving 50% concentration of oxygen in the output gas, at an inlet pressure of 2.5 kg/cm2, a nozzle of minimum 1.25 mm should be used and hence the same is selected.

Conclusion

This design of Dilution Demand Oxygen Regulator is expected to meet all the physical and physiological requirements of high altitude para jumper. Its design offers low breathing resistance providing comfortable breathing. The breathing duration is increased by a factor of almost 1.5 to 2 times when compared to systems without dilution facility. The regulator is expected to meet average and peak flow requirements under normal and stressful conditions. The unit is compact enough to be clipped to the clothing of the para jumper and causes practically no discomfort.

Acknowledgements

The authors express their sincere gratitude to Shri. G.R Agrawal, Director, DEBEL, Bangalore, for his encouragement and guidance in pursuing the work related to breathing regulator. We also thank Wg. Cdr. VS Sachdev, Shri. S.G. Guru Prasad and Shri. B.K. Chandra Shekhar for their technical support. The authors would also like to acknowledge the support extended by the Technical Management Division, DEBEL, Bangalore, for their administrative and editorial help.

References

- High altitude and Hypoxia In: Edholm OG, Weines JS, eds. Principles and Practice of Human Physiology. London Academic Press; 1981. p. :241-307. In:

- [Google Scholar]

- Gillies JA, ed. A Textbook of Aviation Physiology (1st ed). Pergamon Press; 1965. p. :209-289.

- Prevention of Hypoxia, revised by McMillan AJ In: Ernsting J, King P, eds. Aviation Medicine (2nd ed). London: Butterworths; 1988. p. :60-71. In

- [Google Scholar]

- Oxygen Equipment and Pressure Clothing In: Ernsting J, King P, eds. Aviation Medicine (2nd ed). London: Butterworths; 1988. p. :72-111. In

- [Google Scholar]

- The Dynamics and Thermodynamics of Compressible Fluid Flow. Ronald Press; 1953. p. :91-105.