Translate this page into:

Use of digital anthropometric mannequins for human engineering evaluation of workstations in aviation

Abstract

Digital three-dimensional human mannequins are in use worldwide in Computer Aided Design (CAD) of workstations, but till now suitable anthropometric mannequins with dimensions close to Indian pilot population were not available. The Naval version of the Advanced Light Helicopter (ALH) has two crew workstations located in the aft fuselage. These workstations are designed to allow two Naval Observers to track surface targets by radar and underwater targets through dunking sonar as well as disposable sonobouys. The workstations were required to be ergonomically evaluated. Digital anthropometric mannequins corresponding to Indian Pilot population were used along with AutoCAD® drawings of the rear fuselage of the aircraft to study the workspace. Thereafter the stations were physically evaluated with selected subjects. This paper discusses the development and use of digital anthropometric mannequins for ergonomic studies in airborne platforms.

Keywords

Mannequins

ergonomic evaluation

airborne workspace

Aeronautical design agencies worldwide including those in India are extensively using Computer Aided Design (CAD) simulations in helping them design aircraft, but human models approximating our user population have not been available. Thus, for giving initial input to the designers and evaluation of the cockpit or workstation at the drawing board stage itself, a need was felt to develop an appropriate human form for simulating Indian pilot population. After identifying the most suitable software and modifying the mannequins to our population, an opportunity to test it out on actual human engineering evaluation presented when Institute of Aerospace Medicine (IAM) was tasked to evaluate the rear workstation of the Naval version of the ALH.

The ALH Navy is the maritime version of the ALH and differs from the Air Force version in that it has two consoles for radar/ sonar operator in the rear fuselage of the aircraft. The consoles, which would be occupied by Naval Observers, are forward facing and displaced to the left of center of the fuselage. Entry into the aft fuselage is through sliding doors on both sides of the aft fuselage. These doors have a single transparent jettisonable window through which the aircrew would escape in an emergency. Side view of the general layout of the aircraft is depicted in Fig 1 and Fig 2.

- Diagrammatic side view of the workstation

- Side view of aircraft

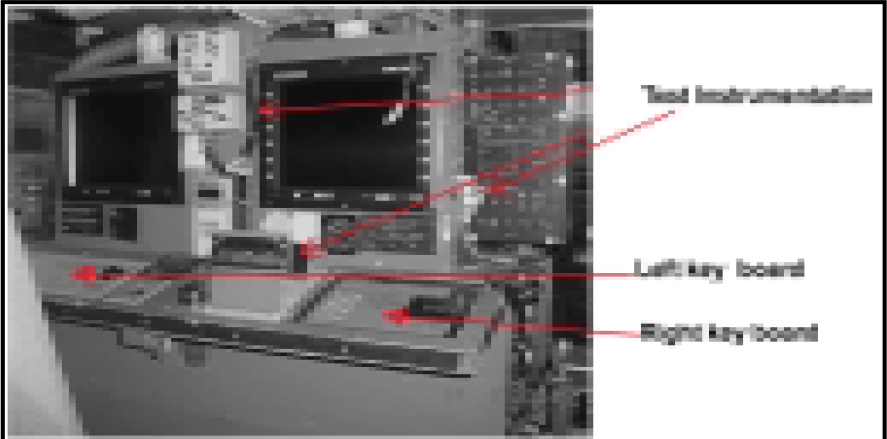

The consoles are dominated by a vertical radar/ sonar scope that displays the required sensor data, and the controls are a keyboard and roller ball (Fig 3).

- View of consoles

The crew seat is equipped with a 5-point restraint system. Detailed aeromedical evaluation of the same had been carried out at this Institute [1]. A personal survival pack (PSP) is placed under the seat cushion on which the observer sits. The Mae West that is worn by the observer is attached to the PSP by three connectors.

Material and Methods

MannequinPRO® from NexgenErgo, Canada was identified as the most suitable to construct mannequins corresponding to the 5th, 50th and 95th percentile. Anthropometric data currently in use was compiled by Kapur et al in 1987 [2] and this formed the basis of anthropometric inputs for the mannequins. The workstation was first evaluated by examining engineering drawings on Auto CAD® and then by physical evaluation with subjects falling in 5th to 95th percentiles of the Indian aircrew population. The aircraft evaluated was Prototype Navy (PTN) as well as IN 703 as this aircraft had a slightly different console layout. The factors examined were reach, clearances, visual requirements, limb position and comfort.

Digital Mannequins. Software from MannequinPRO® was used to develop the mannequins. The initial mannequin posture chosen in this case was a seated erect position. Thereafter, the limbs were manipulated to the required position. The movement of each joint is restricted within realistic joint constraints. There are several different types of graphical representation available for the mannequin model, including wire mesh, frame, hidden line and two -shaded representations. Hidden line was generally the clearest representation for our purposes. Anthropometric parameters of the subjects used in this study are given in Table 1 (percentile values in parenthesis).

| Parameter | Subjects | ||

|---|---|---|---|

| AKR | JJ | CV | |

| Sitting Height | 90.7(70) | 81.3(1) | 95.9(98) |

| Eye level Height | 80.4 | 72.3 | 85.4 |

| Thigh Length | 64(99) | 55.2(5) | 62.4(95) |

| Leg Length | 114(95) | 100(5) | 116(97) |

| Arm Reach | 87.4 (95) | 78.3(15) | 87.3(95) |

Results

Mannequin Studies

Reach. The 5th percentile mannequin was used with the seat in the lowest and forward most position. It was found that the keyboard and roller ball were within reach but the console was out of reach.

Clearances. The 95th percentile mannequin was used with the seat in the rearmost and lowermost position. It could be measured that overhead clearance was 20.8 cm, knee console clearance 14 cm, and keyboard to knee vertical clearance was 17.5 cm. Space was not adequate for the foot under the console.

Visual Field. In both the mannequins the primary visual field was below the optimum level and the console would need to be lowered to come within the primary visual field. The distance of the eye from the console and the floor was 64 to 70 cms and 112 to 114 cms respectively.

Limb position. Limb angles were measured and are given in Table 2 below:-

| 5thpercentile | 95thpercentile | |

|---|---|---|

| Arm torso | 30° | 40° |

| Elbow | 121° | 126° |

| Thigh trunk | 108° | 90° |

| Thigh leg | 96° | 102° |

Subject Trials

-

Reach.

The minimum percentile subject was used for the trials with reach. Seat was adjusted in the highest position. It was found that he could easily reach the keyboard and roller ball but he could not reach the vertical console with the harness locked. The observer sitting on the left could not reach the emergency window-jettisoning lever as the space for reaching it was restricted by the console.

For the observer on the right, the emergency lever was again too far forward to reach while seated. This lever could be operated only after un-strapping the restraint harness and getting out of the seat.

-

Clearances.

Clearances were checked with the seat in the lower most position. The higher percentile subject was used and clearance from the helmet to the roof, knee to the console and thigh to the undersurface of the console was found adequate.

Overhead clearance with the subject CV and seat in lowermost position was 11 cm.

There was about 13 cm space between the knee and the console and 14 cm between the knee and undersurface of the keyboard.

Clearance for the feet was not adequate. The space below the console did not allow the feet to be placed comfortably by the higher percentile subjects.

-

Visual Field.

The upper half of the scope of the radar and sonar console was found to be above the horizontal vision line of the subject when the seat was adjusted for the subject’s height. However, if the higher percentile pilot adjusted his seat 4-5 cm above lowest point the console came into his primary field of view.

The subject’s eyes were 60+2 cm away from the screen and 108 cm above floor and this was taken as Design Eye Point (DEP).

DEP of the left workstation in both the aircraft evaluated was 2 cm below the middle of the screen.

DEP of the right workstation in PTN aircraft was situated 2 cm below and 6 cm to the left of the middle of the screen. In IN 703 the lateral displacement had been corrected as the seat had been moved to the right by 6 cm.

Limb Position and Comfort. The keyboards were placed at an angle of 15° to horizontal and as such were within the prescribed range of comfort [3]. However the height of keyboards from the floor was too high and this caused the hands of the operator to work above the level of the elbow. This would be a cause of discomfort and early fatigue. The keyboard on the left console was not directly in front of the operator but displaced by 8 cm to the left. This was uncomfortable to operate. The other observations pertaining to height of keyboard were the same as PTN aircraft. The thigh leg angles were close to 90° and this would be uncomfortable after some time [3]. No footrest was provided.

Discussion

Variation between mannequin studies vis-à-vis subject trials

The mannequin study of the workspace could not be done in any other plane except the two-dimensional one due to the reason mentioned above; therefore the left displacement of the console and the inability to reach the emergency door lever which was displaced to the right and left of the plane under study could not be determined.

There was a difference of 9 cm between the overhead clearance found on the mannequin to that same found on the subject. This can partly be explained by the absence of a helmet on the mannequin, which would account for 4-5 cm. The difference in knee clearance of 3.5 cm between the knee and the undersurface of the keyboard could be explained by the absence of footwear on the mannequin.

There was a difference of 4-8 cms in the fore and aft plane between the DEP found in the two studies. DEP is very dependent on slouch of the torso and head position and varies from subject to subject. Thus variations of this magnitude in DEP in this plane are not especially significant.

Effect of forward movement of shoulder girdle to evaluate reaches cannot be simulated with the mannequin.

The results clearly show that there are small differences between the computer based simulations and the subject based trials. Sources of error have been highlighted above.

By themselves the mannequins are useless; they have to be used with appropriate engineering drawings. AutoCAD® was easily available and amongst others, required less computing power and the least training. Thus it emerged as the most suitable CAD software for use. Other suitable software that could be used is 3D Studio Max.

The small differences between the simulations and actual trials would reduce when these disadvantages are known and compensated for and this would naturally come with more hands on experience with the software. The initial trials with import of AutoCAD® drawings into this software and vice versa were hampered by the difficulties encountered in matching the scale of both the drawings. This matching of scale assumes utmost importance if there has to be any meaningful findings from the simulations. However with experience this could be accurately achieved. Ultimately working with 3D drawings would address the problem of evaluations in planes other than fore and aft.

Advantages of using digital mannequins

All sizes and body morphology type of subjects can be used. Combinations that are very rarely found in real subjects can be simulated.

Limbs and hands can be manipulated to actual positions that would be required to operate a control.

Whole body movements like simulated pull out trials can be performed. Areas of contact or those with reduced clearance can be identified before actual trials are done.

Size of mannequin’s limbs and torso can be measured and altered. Joint angles, visual angles and limb positions can also be measured accurately.

Can work with 3D solids as the mannequin is in 3D, however till now only 2D drawings were available for trial.

Easy import and export to and from Auto CAD®.

Disadvantages of digital mannequins

Effects of clothing, shoes and helmet cannot be simulated and thus extra allowance has to be made for this. Head posture and head clearance could not be reproduced due to the lack of helmet.

Body compressibility is not built into the software. Thus the compressibility of the buttocks and thighs is not catered to and allowance has to be made for this.

Effect of restraint harness cannot be considered and this effects accurate measurements.

The software is expensive, not in absolute terms, but in licensing as software is licensed to a single machine.

MannequinPRO® from NexgenErgo was found to be suitable for use in preliminary assessment of airborne workstations as a pointer to areas of man-machine ergonomic incompatibility. Some of the factors mentioned above like compressibility and the effects of harness and clothing need to be taken into account. Notwithstanding the above, mannequin evaluation cannot be a substitute for trials with subjects clothed in full flying clothing.

References

- Compatibility of sea variant PSP with FE crew seat for Naval version of ALH Bangalore: Institute of Aerospace Medicine; 2001. Test Report No. IAM TR/4/2001

- [Google Scholar]

- To formulate an aircraft station geometry for cockpit design and layout for military aircraft. AR&DB Project 317 In: Part A: An Anthropometric Survey of Indian Air Force Aircrew. 1988.

- [Google Scholar]