Translate this page into:

Effectiveness of Gel Cooled Vest in alleviating Heat Stress among Air Force Personnel working on Tarmac: A Field Study

Corresponding author

Abstract

Introduction:

High temperature on airfield tarmac in summer months could adversely affect efficiency of technicians servicing the aircraft. To improve comfort of these technicians, feasibility of using a cooling vest having Phase Change Material (PCM) was conducted in a forward Air Force base.

Methodology:

100 randomly selected healthy tarmac technicians were divided equally into Study Group (SG) and Control Group (CG). Subjects in the SG were fitted with cool vest over overalls and subjects in CG wore working overalls. Both groups performed similar tasks for three hours with ambient temperature of 35ºC with 60% RH. Heart rate (HR) and core temperature (Tc) were recorded at 30 min intervals. Net sweat loss and subjective comfort provided by the vest were also assessed.

Results:

The collected data was analysed using Repeated Measure ANOVA. Mean differences in HR, Tc, average sweat loss and Physiological Strain Index (PSI) between SG and CG were found to be significant. Questionnaire survey revealed a positive response on comfort and acceptability to the vest.

Conclusions:

The PCM based cool vests were found to be effective in alleviating heat stress for 120 min to 150 min. PCM packs need to be replaced to maintain same level of protection from heat stress.

Keywords

Heat Stress

Heart Rate

Sweat Loss

Physiological Strain Index

Introduction

One of the hottest working environments in the Indian Air Force operational setting is the aircraft maintenance carried out on the airfield tarmac. The runway and tarmac temperature in many Air Force stations in Western and South Western sectors touches 50º C in summer [1]. The technicians conducting first-line servicing of aircraft at the Daily Servicing Stations (DSS) within the Squadrons are exposed to high ambient temperature conditions. High environmental temperatures when coupled with high humidity could exceed the tolerance limit of the personnel exposed to heat conditions leading to performance decrement [2].

The highly skilled technical workforce maintaining the state-of-the-art aircraft of Indian Air Force need to remain at their highest level of work efficiency to carry out their duties. Heat stress not only causes well recognised clinical entities like heat stroke, hyperpyrexia, exhaustion and syncope, it can adversely affect the psychomotor and cognitive responses, affecting the functional efficiency of a worker in a highly skilled work environment [3]. Various methods have been tried to alleviate the heat stress in aviation and elsewhere, with varied levels of success [4]. Provision of a personal cooling system in the form of microclimate cooling appears to be one of the best option for keeping the individual in a state of physiological and subjective comfort [5].

Cooling vestsusing Phase Change Material (PCM) packs have been found to be efficient in effective control of the core temperature and are being used by fire fighters and armored vehicle crew. There is a need to introduce such personal cooling system to alleviate the heat stress among the maintenance personnel working on the airfield tarmac in Indian Air Force. However, the utility of these vests need to be objectively evaluated on the airfield tarmac before planning their introduction in the Air Force.

Aim & Objectives

The present study was conducted with the aim to study the efficacy of Cooling Vest having Phase Change Material (PCM) in offsetting heat stress in actual field conditions on the airfield tarmac among maintenance personnel of Indian Air Force. The objectives of study included (a) Monitoring of physiological parameters of heat stress, viz.heart rate, core temperature and net sweat loss in personnel working on airfield tarmac, (b) To correlate the efficacy of the Cooling Vest in providing protection against heat stress (c) To evaluate the acceptability of the cooling vest by aircraft maintenance personnel working on airfield tarmac.

Methodology

This study was carried out in one of the premier Air Force Station situated in the North Western part of India. The study was conducted for duration of 03 hrs on 03 days. The average ambient temperature was between 33-34.5 deg C with 60% RH. The study was conducted on the days having calculated discomfort index (DI) in excess of 30 deg C which was calculated by using the formula DI= 0.5 T db + 0.5 Twb (deg C).

Subjects

A total of 100 technicians working on the tarmac and involved in the first line servicing participated in this study. They were divided into two groups of 50 each forming ‘Study Group’ (SG) and ‘Control Group’ (CG). All participants were in full medical category with no pre-existing morbidity. The participants were explained in detail about the study protocol and the Informed consent was obtained from them. The study protocol was cleared by the Hospital Ethical Committee.

Equipment Used

The PCM based cooled vest designed and manufactured by the Defence Research and Development Organisation (DRDO) was used for the study. These cotton vests had multiple pockets over the heat sensitive areas of the torso wherein the pre-cooled PCM packs were placed. Finger tip pulse oxymeter, ‘Ready Oxy’, was used to monitor the heart rate during exposure to heat stress. An infrared thermometerwas used to measure the instant aural temperature as a representation of core body temperature. Digital weighing scale with an accuracy of ±10 g was used to measure the body weight of the subjects.

Study Protocol

One day prior to heat exposure protocol, the subjects were briefed about the procedure. They were advised to refrain from alcohol, to have adequate rest and sleep. Next day, the following procedure was followed for the heat stress exposure:-

Preparation of the Subjects. Participants reported 30 min before start of the heat stress protocol. After resting for 20 min, their heart rate (HR), core temperature (CT) and near nude body weight were recorded to obtain baseline data. The HR and CT of the subjects in both SG and CG were recorded at 30 min intervals throughout heat exposure.

Recording of Environmental Temperature. The ambient atmospheric temperature parameters including Tdb and Twb, the (DI) were calculated and recorded at every 30 min interval for the complete duration of 03 hour of exposure.

Clothing of Subjects. Subjects in the SG group were fitted with the PCM based Cooling Vest over their working overalls. Controls were wearing their normal working overalls only.

Work Environment and Allowances. Both the groups (SG and CG) performed similar tasks on the airfield tarmac. The subjects were allowed to drink water and also to pass urine when required. The quantity of additional water intake and urine output was noted and was utilized in calculating the net sweat loss.

End Points for Heat Exposure. It was decided to terminate the heat exposure in any subject attaining an HR in excess of 180 bpm for 3 min or core temperature reaching 39.2º C, indicative of severe heat stress [6].

-

Post Heat Exposure Activities

-

Assessment of net sweat loss. Subjects were weighed at the end of the heat exposure to assess the sweat loss corrected to additional water intake and urine output by applying the formula given below:-

Net sweat loss = initial bodyweight – (final bodyweight) + [water intake – (urine output)]

Feedback from subjects. A questionnaire survey was conducted at the end of the heat exposure for subjective assessment of the difference between the non-vest and vest conditions.

-

Assessment of heat strain. The net change in core body temperature (Tre) and heart rate (HR) from the basal readings were noted. The physiological strain index (PSI) at every 30 min interval was calculated for the entire duration of exposure for each of the subject to assess the heat strain imposed by using the formula given below:-

Statistical Analysis

The data obtained was analysed using Statistica software and Repeated Measure of Analysis of Variance (ANOVA) to find out difference between and within the groups. Student’s ‘t’-test (unpaired) was used to find out difference in the net sweat loss between vest and non vest conditions keeping the confidence level at 95% (p= 0.05).

Results

The physical characteristics of the subjects participated in the study is given in the table below.

| Physical character | Control group (n= 50) | Study group (n= 50) |

|---|---|---|

| Age (yr) | 28.4 ± 4.3 | 26.9 ± 4.9 |

| Height (cm) | 170 ± 4.7 | 169 ± 5.9 |

| Weight (kg) | 67.3 ± 7.1 | 64.7 ± 7.1 |

The observed changes in the mean heart rate (HR), average core body temperature(TAural), average net sweat loss and calculated physiological strain index (PSI) between the control and study groups on exposure to heat stress is given in the tables 2-5.

| Time → | 0 min | 30 min | 60 min | 90 min | 120 min | 150 min | 180 min | |

|---|---|---|---|---|---|---|---|---|

| Heart rate (bpm) | Mean SD | 73.38 ± 4.88 | 77.84 ± 4.37 | 81.06 ± 4.02 | 84.32 ± 3.80 | 86.64 ± 3.47 | 9.48 ± 3.19 | 93.34 ± 3.35 |

| TAural (deg C) | Mean SD | 36.67 ± 0.13 | 36.92 ± 0.16 | 37.08 ± 0.16 | 37.24 ± 0.19 | 37.4 ± 0.17 | 7.56 ± 0.18 | 37.81 ± 0.19 |

| Time → | 0 min | 30 min | 60 min | 90 min | 120 min | 150 min | 180 min | |

|---|---|---|---|---|---|---|---|---|

| Heart rate (bpm) | Mean SD | 72.78 ± 4.48 | 75.94 ± 5.10 | 76.96 ± 4.68 | 77 ± 4.52 | 77.64 ± 4.05 | 81.02 ± 3.77 | 85.16 ± 3.52 |

| TAural (deg C) | Mean SD | 36.61 ± 0.09 | 36.82 ± 0.14 | 36.75 ± 0.13 | 36.71 ± 0.12 | 36.79 ± 0.11 | 36.99 ± 0.16 | 37.26 ± 0.28 |

| Wt in kg Pre- Exposure | Wt in kg Post- Exposure | Net sweat loss in gms | ||

|---|---|---|---|---|

| Control group | Mean SD | 67.32 ± 7.13 | 66.72 ± 7.11 | 927 ± 185.54 |

| Study group | Mean SD | 64.7 ± 7.09 | 64.53 ± 7.07 | 452.8 ± 99.53 |

| t | 1.84 | 1.54 | 15.92 | |

| p | 0.06 | 0.12 | 6.12 | |

| Time → | 30 min | 60 min | 90 min | 120 min | 150 min | 180 min | |

|---|---|---|---|---|---|---|---|

| Control group | Mean SD | 0.65 ± 0.22 | 1.03 ± 0.30 | 1.49 ± 0.34 | 1.87 ± 0.35 | 2.3 ± 0.39 | 2.86 ± 0.52 |

| Study group | Mean SD | 0.51 ±0.23 | 0.48 ± 0.31 | 0.41 ± 0.21 | 0.54 ± 0.20 | 1.0 ± 0. 29 | 1.68 ± 0.55 |

The changes in the heart rate (HR), core temperature (TAural) and physiological strain index (PSI) between CG and SG were compared using repeated measures of ANOVA. The heart rate exhibited significant main effect of both exposure to temperature (F=851.85, p=0.000) and vest (F= 54.94, p= 4.46). Additionally, the interaction between the two main effects (group x exposure) was also significant (F=87.50, p= 0.00). The core body temperature (TAural) also exhibited similar significant main effect on exposure to temperature (F=531, p=0.00) and vest (F=263, p=0.00). Additionally, interaction between the two main effects (group x exposure) was also significant (F= 83, p=0.00). The response of physiological strain index also exhibited significant interaction between exposure to temperature (F=497.69, p= 0.00) and vest (F=389.61, p=0.00). The interaction between the two main effects (group x exposure) was also significant (F= 72.07, p= 0.00).

Since, the interaction ‘F’ value was found to be significant, further Post-hoc analysis was carried out using Tukey’s HSD to find out the difference within and between the groups for the variables under study ie, HR, TAural and PSI. The findings of post-hoc analysis indicated that there was no significant difference in the HR between the two groups at base line (0 min) (p= 0.999) and at 30 min of exposure (p=0.572). Further, it was observed that the heart rate in both CG and SG differed significantly at all further measurements i.e. At 60 min, 90 min, 120 min, 150 min and 180 min (Fig 1).

- Graph showing the response of heart rate on exposure to heat stress between vest group and non-vest group (n= 100)

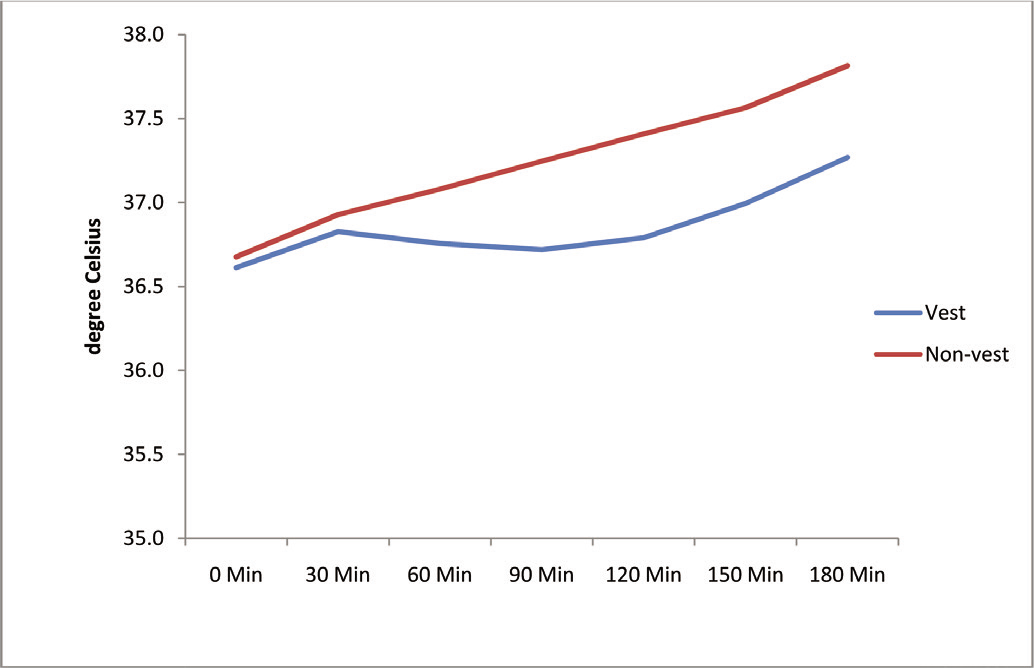

The post-hoc analysis indicated that the difference in aural temperature at baseline and at 30 min of exposure were not significant (p=0.999 and p=0.572 respectively). However, significant differences between in both the groups was observed at all other exposures i.e. 60 min, 90 min, 120 min, 150 min and 180 min. (p<0.001). The study group recorded less value of aural temperature as compared to control group (Fig 2).

- Graph showing the responseof core body temperature on exposure to heat stress between PCM vest group and non vest group (n= 100)

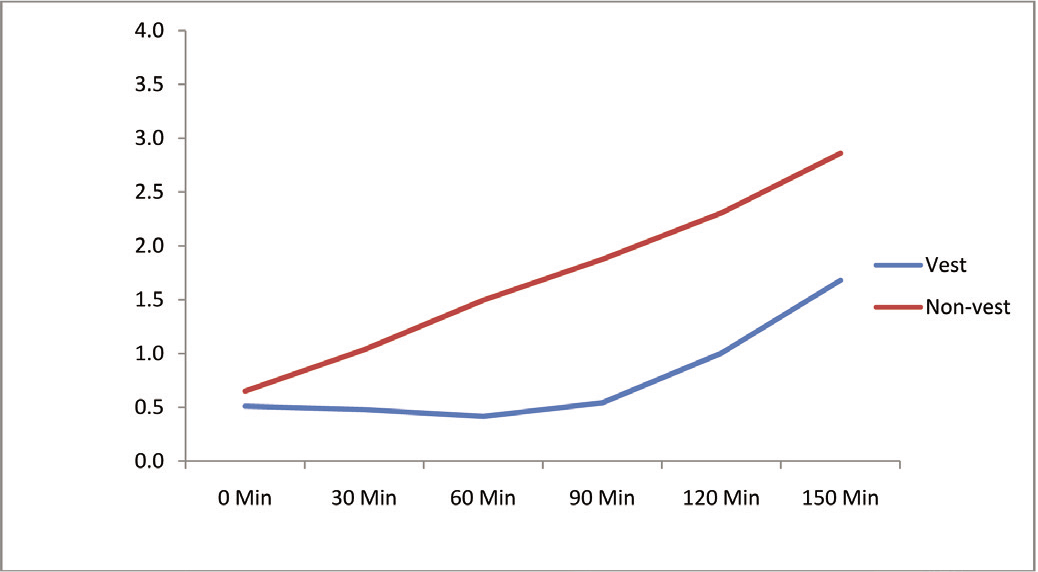

The physiological strain index in both control group and study did not show any significant mean difference from baseline values to 30 min of exposure (p- 0.689). However, PSI measured at 60 min, 90 min, 120 min, 150 min and 180 min of exposure to heat stress, the groups showed significant difference in the means (p<0.001). The mean PSI was found to be lower in the study group as compared to the control group (Fig 3).

- Graph showing calculated physiological strain index on exposure to heat stress between PCM vest group and non vest group (n= 100).

Discussion

Heat stress is an important problem encountered among the tarmac technicians servicing the aircraft during summer months. Various methods to alleviate the heat stress have met with varied success. The basic motto of these cooling methods was to reduce the heat load imposed on the individual enabling them to perform their tasks efficiently.

The human body consists of several regions with distinct thermoregulatory characters. Cooling of torso and upper arms plays is an effective role in removing heat load [7]. Cooling of the chest has the advantage of direct effect on the heart area and the relatively large surface area cooled, which results in very efficient and effective cooling. Studies carried out on analysis of the PCM based cooled vest in the laboratory have demonstrated significant reduction of heat load[8]. The study demonstrated improvement in the whole body and torso thermal sensations. However, no study has been conducted till date on the heat load imposed on the tarmac technicians and the methods to alleviate the same.

The present study was undertaken in an attempt to evaluate the PCM based cool vest in alleviating the heat stress and to make recommendations for use for the technicians of IAF working on the tarmac during summer months.

Body Response to Heat Stress with and without PCM Vests

Exposure to heat stress for 03 hours resulted in rise of the average core body temperature(TAural)in CG to 37.8oC from the pre-exposure value of 36.6oCwith a mean increase of 1.2ºC. The mean TAural rose to 37.3ºC from pre-exposure value of 36.6ºC in the SG with a mean increase of 0.6oC. The graphical representation of mean core body temperature remained flat line till 120 min and thereafter, it increased linearly with time.The reduction in core body temperature offered by the PCM vest was highly significant at 30 min into the exposure. The rise in the core body temperature in the SG was less throughout the duration of exposure as compared to the control group, and the difference was statistically significant.

Mean heart rate (HR) in the CG rose from pre exposure value of 73 bpm, to 93 bpm at the end of the exposure, with an increase of 20 bpm. This rise in the HR was within the upper safe limit of body heating and the rise was linear with the duration of exposure as also observed in few other studies (2,6]. On exposure to heat stress, the heart rate rises to increase the cardiac output as demanded by the increased cutaneous blood flow [9].Since blood is the medium of heat transfer from deep body to the skin, it implies that the cardiac output and HR would have a linear relationship with increased core temperature and heat accumulation. Such a relation has been observed by the other workers also [10]. In SG, the HR at the end of the exposure was 85 bpm with a mean increase of 12 bpm from the pre exposure value of 73 bpm.The reduction in HR observed in the SG was significant from the CGafter 30 min and thereafter. The graphical representation of heart rate curve in SG almost maintained horizontal line from 30 min till 120 min in to the exposure and thereafter started rising linearly till the end. The difference in HR from study group and control group was significant from 30 min onwards till the end of the exposure.

Sweat loss is another parameter indicating the physiological strain produced by the heat stress. On exposure to heat stress, the sweat production increases in quantity to increase the evaporative heat loss. In the present study, the mean net sweat loss measured in the control group was 927 gm as compared to 452 gm in the study group these values were within the known upper safe limit of body heating. The findings of this study are similar to the ones observed during other studies [10].

The physiological strain index (PSI) has been found to be the most reliable of the heat strain indices [11]. Analysis of the physiological strain index revealed that 20 subjects in the control group were under mild heat strain after (PSI value of > 3) whereas the subjects in the study group experienced negligible heat strain (PSI value <2). It is evident the heat stress exerted on the subjects during both CG and SG exposures was not severe. The PSI calculated for each individual separately revealed that only 20 subjects in the control group had experienced mild heat strain (PSI of >3) whereas all subjects in the study group experienced negligible heat strain (PSI<2).

The questionnaire survey conducted at the end of the heat exposure for the subjective assessment indicated high degree of positive response for use of cool vest for alleviating the heat stress while working on the tarmac in the summer months.

Mechanism of Action of PCM Cooled Vest

Frozen PCM packs contained in the cooled vest formed a microclimate cooling system and acted as a barrier between the body and the hot environment. Thus it performs the role of a heat sink and absorbed heat radiation and convection of hot air flow from the body surface as well as the environment. The PCM substance absorbs large quantities of heat without significant rise in temperature until the material was transformed into liquid/ gel phase. There was less effect of the environmental heat load on the body and also, better heat dissipation from the body even for a smaller rise in the body temperature.

Limitations of the Study

The study was conducted on the tarmac of the airfield for duration of three hours continuously under moderate heat stress conditions. The maintenance personnel servicing the aircraft participated in the study. They were allowed to drink water ad- libidum during the study period as it was important to ensure that nobody drops-out due to excess of thirst or dehydration. Similarly they were also allowed to pass urine if there was an urge to do so. The quantity of additional water intake as well as the quantity of urine passed was considered while calculating the net sweat loss by applying the formula given below:-

The net sweat loss obtained by applying the above formula may be slightly different from the actual loss, as it did not take account of the water loss due to respiration. However, this was the most practical way to do it in the field conditions where the study was conducted.

Conclusions

The cool vests containing PCM gel packs did offer cooling benefit to the individuals during exposure to heat stress while working on the airfield tarmac. The total heat strain on the subject wearing cool vest was significantly less for duration up to 120 min as compared to subjects not wearing the cool vest on exposure to heat stress.The physiological mechanisms of heat loss viz. sweat loss and increased blood supply was not hampered. However, it is evident that, cooling effect offered by the vest was approximately 120 min (2 hr) after which the PCM packs need to be replaced to maintain the same level of protection from heat stress.

References

- Heat stress in aviation at Jamnagar: A Field study. Indian J Av Med. 1984;28(1):21-32.

- [Google Scholar]

- Human tolerance for high temperature aircraft environments. J Av Med. 1954;25:515-522.

- [Google Scholar]

- Psychomotor deterioration during exposure to heat. Aviat Space Environ Med. 1980;51(5):607-610.

- [Google Scholar]

- Comparison between different auxiliary cooling devices in a severe hot/ dry climate. Ergonomics. 1986;29:41-48.

- [Google Scholar]

- A review of today’s personnel cooling technologies [Internet] [Cited 2018 Aug 06] Available from: http/home.microsoft.com/bobg@microclimate.com1999

- [Google Scholar]

- Head and torso cooling during simulated cockpit heat stress. Aviat Space Environ Med. 1983;54(6):496-499.

- [Google Scholar]

- Personal cooling with phase change materials to improve thermal comfort from a heat wave perspective. Indoor Air. 2012;22(6):523-30. [Internet] [Cited 2018 Aug 10]. Available from https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1600-0668.2012.00778 x Epub 2012 Mar 20

- [Google Scholar]

- Human cardiovascular adjustments to exercise and thermal stress. Physiological Reviews. 1974;54:75-142.

- [Google Scholar]

- Efficacy of head cooling in alleviating heat stress in acclimatized Indian subjects. (dissertation) Bangalore University, Bangalore). :93.

- [Google Scholar]

- A physiological strain index to evaluate heat stress. Am J Physiol. 1998;275:R129-R134.

- [Google Scholar]